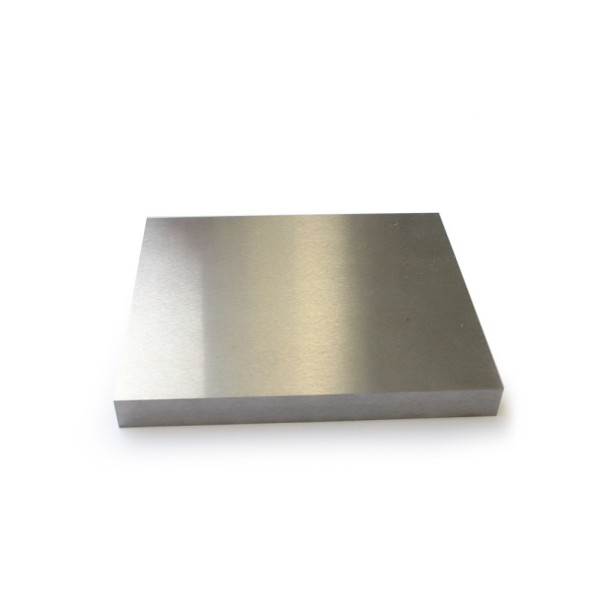

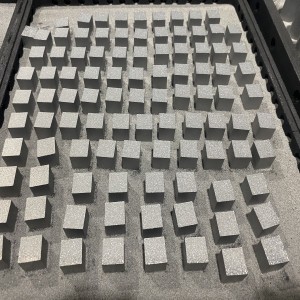

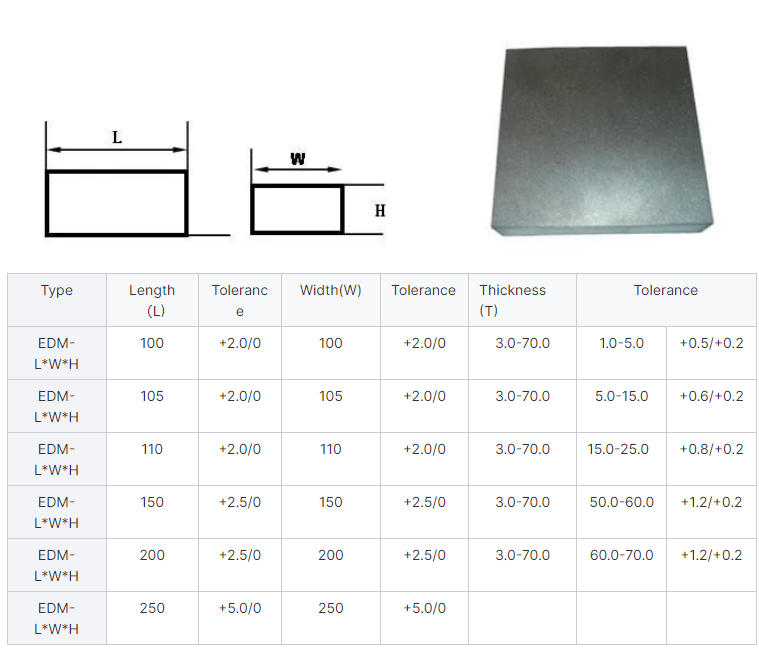

YG8 K20 K30 5*100*100mm 20*100*100mm Tungsten carbide plate for Making Wear-Resistant Parts

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment,while,If there is soecific requests on delivery time.We can make change according to clients’ request,so a shorter delivery time is absolutely available.

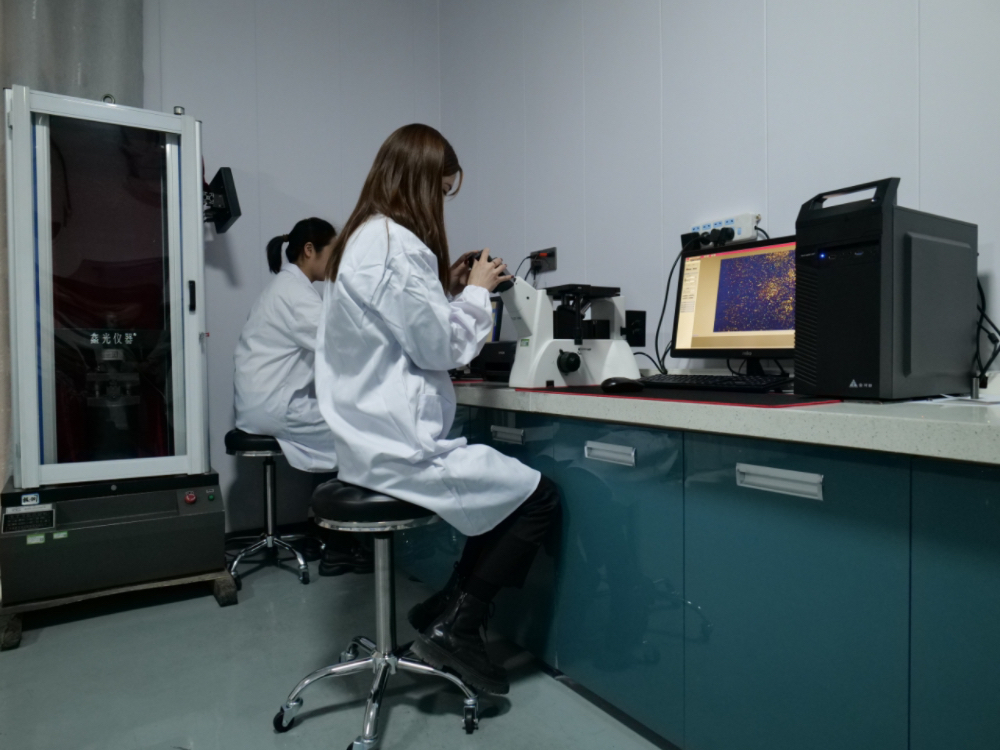

our company

The speed of the finishing roll is high, and the final rolled product must have a certain surface quality, for which hardness and wear resistance are the main requirements. Then consider the wear resistance that the roller should have when used. Since the wear mechanism of rolls is very complex, including mechanical stress, thermal effects during rolling, cooling, chemical effects of lubricating media and other effects, there is no unified index to comprehensively evaluate the wear resistance of rolls. Since hardness is easy to measure and can reflect wear resistance under certain conditions, the radial hardness curve is generally used to approximately express the wear resistance index of the roll.