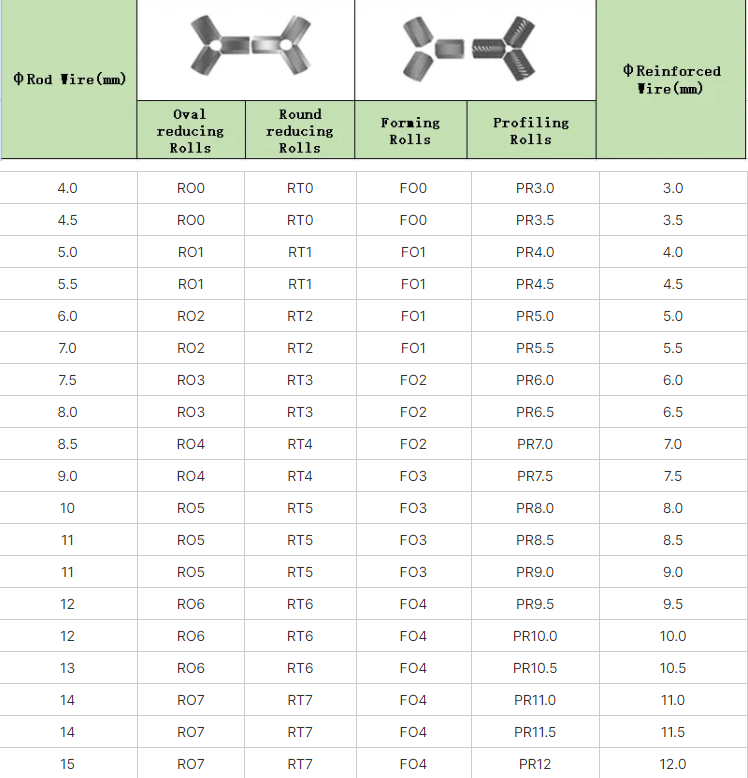

YG15 Three dimensional carbide rolls tungsten carbide roller rings use for cold milling steel bar

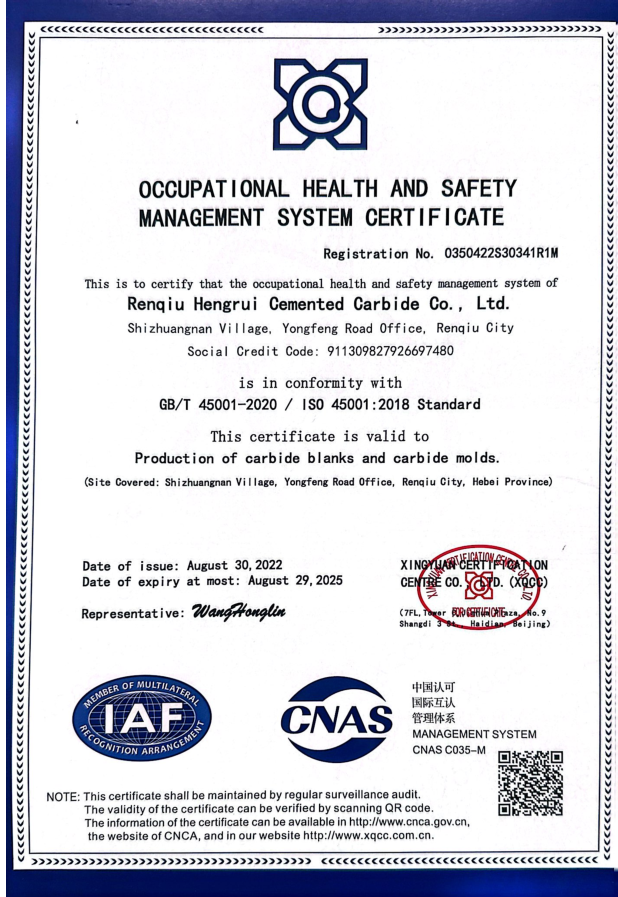

Our company always adheres to the marketing concept of "earning the trust of users with superior quality, meeting users' needs with enthusiastic service, saving users' time with fast methods, and solving users' problems with advanced technology", and creates jointly with customers and friends. brilliant.

Company mission: Committed to becoming a domestic first-class cemented carbide "finished tool" manufacturing enterprise that creates high quality, provides quality services.

Entrepreneurial spirit: Pursue perfection from excellence, seek success from sincerity

Quality policy: sophisticated tools, carefully manufactured, and fully committed to helping you build a well-known brand

Quality goal: Continuously improve product quality, quickly satisfy the market, and become a strong carbide tool enterprise.

1. What are cemented carbide rollers used for?

Cemented carbide rollers are used in the production of rebars. They are known for their long wear resistance and service life, making them ideal for the demanding process of rebar production.

2. What are the benefits of using cemented carbide rollers?

The main benefits of using cemented carbide rollers include long wear resistance, long service life, and the ability to be customized for specific production needs. These rollers are designed to withstand the demanding conditions of rebar production.

3. How do cemented carbide rollers contribute to the production of rebars?

Cemented carbide rollers play a crucial role in the production of rebars by providing long-lasting wear resistance and customizable solutions. This helps to ensure efficient and high-quality rebar production.