Tungsten carbide roller used on the stretch reducing mill for bars

Since the thermal conductivity of the tungsten cemented carbide roll is high, the heat dissipation effect is good, and the time at which the surface of the roll is at a high temperature is short so that the high-temperature reaction time between the roll and the harmful impurities in the cooling water is short. Therefore, the tungsten cemented carbide roll is more resistant to corrosion and cold and hot fatigue than the tool steel roll

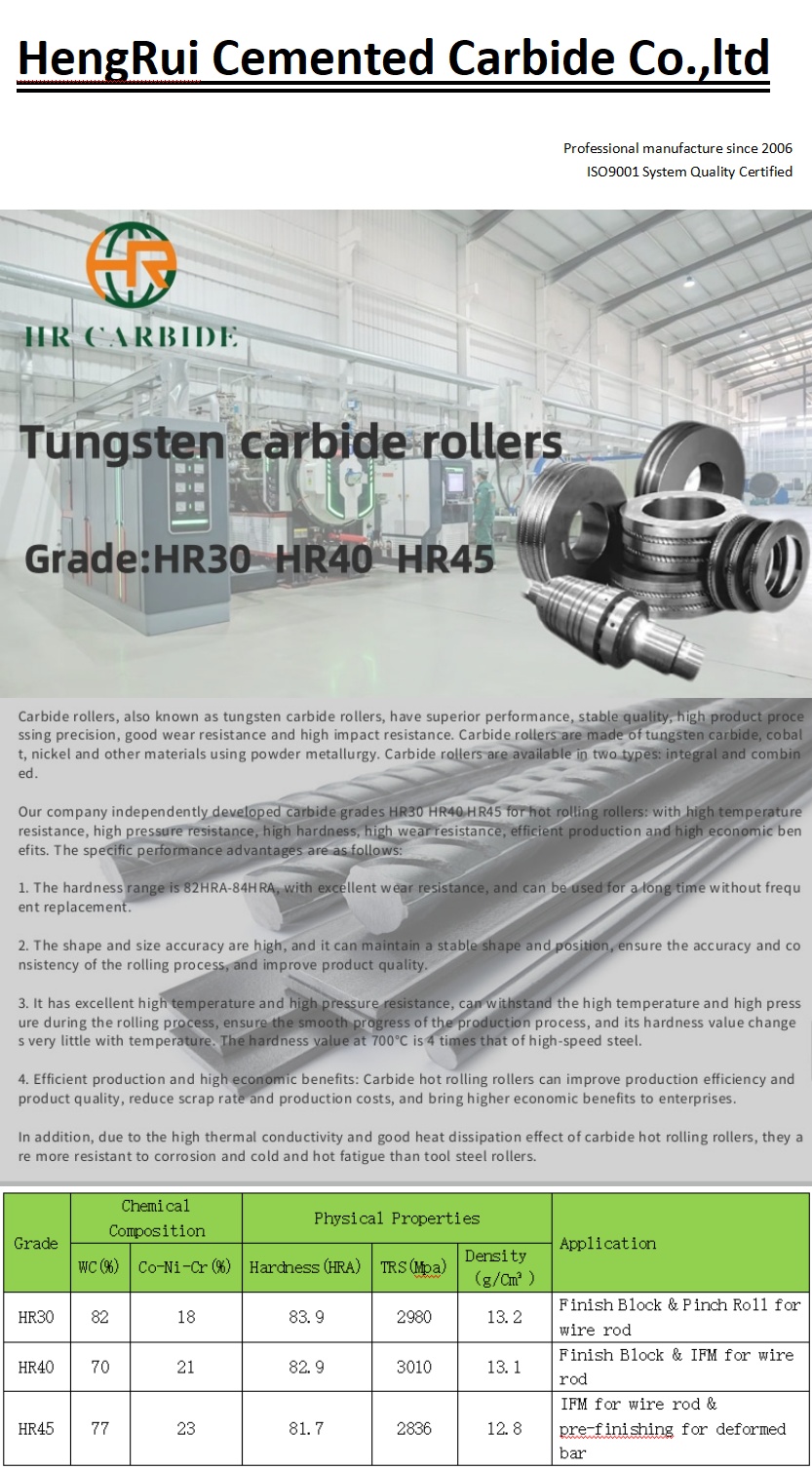

1. What are the commonly used brands of tungsten carbide rollers?

There are different grades according to different materials and processing temperatures. Cold rolling generally uses YG15 YG11 and other brands, and hot rolling uses HR30 HR40 HR60 and other brands containing heat-resistant components.

2. What are your advantages?

Our rollers have been verified by the market for many years and have a good reputation. We are direct manufacturers and can provide the lowest price.

3. What technical support do you provide?

We can customize and recommend the most suitable rollers according to your machine