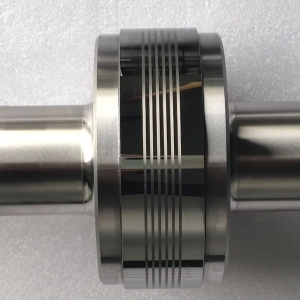

HR carbide Supply Tungsten Carbide coated Roller Wholesale Factory

Another important factor to consider when choosing the right carbide rolls for your production needs is the required surface finish of the processed material. The surface finish can affect the quality and performance of the final product. For example, if you need a smooth and polished surface finish, you may need to choose a carbide roll with finer grain size. Our team at HR carbide can help you determine the required surface finish for your specific production needs and recommend the appropriate carbide roll.

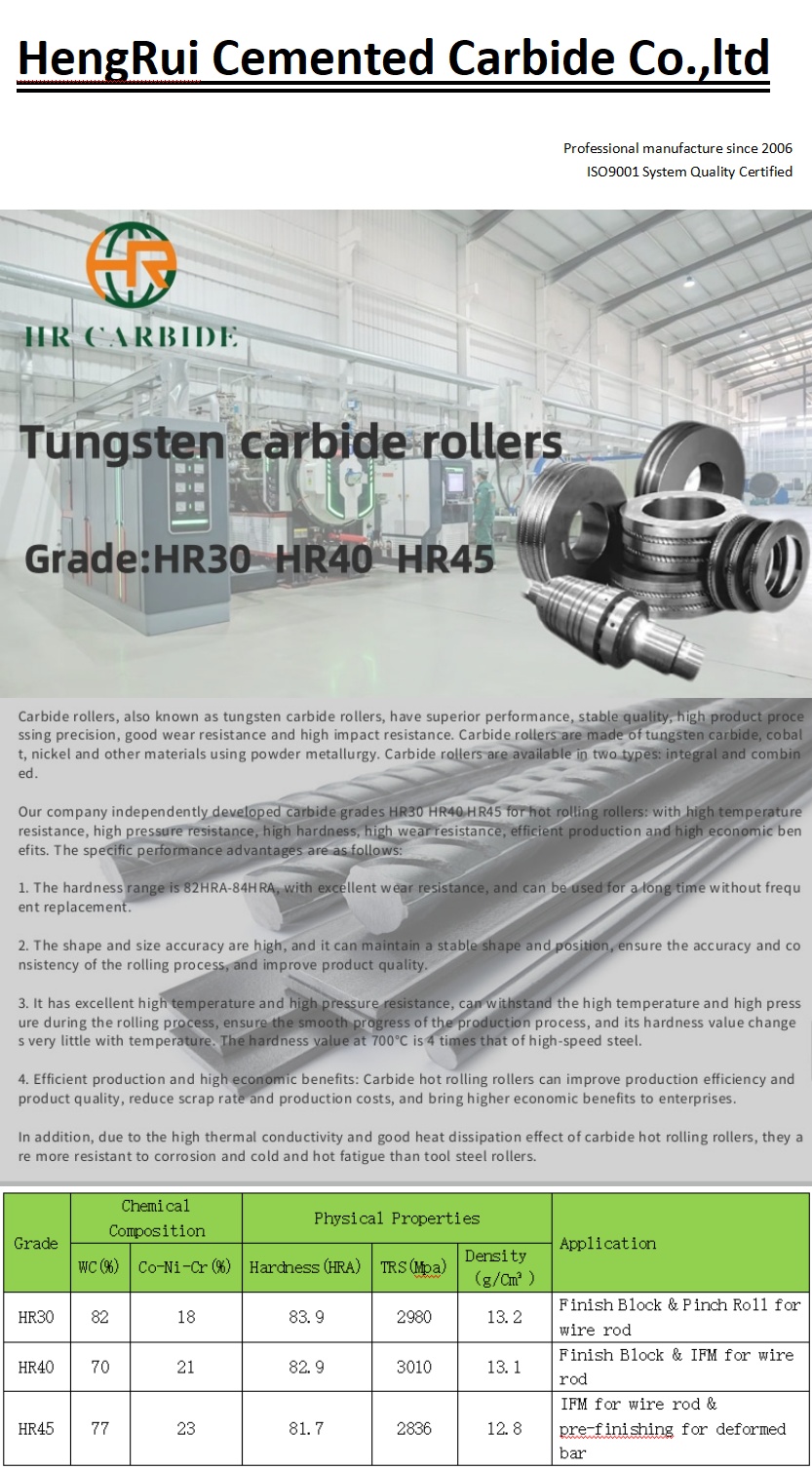

1. What are the commonly used brands of tungsten carbide rollers?

There are different grades according to different materials and processing temperatures. Cold rolling generally uses YG15 YG11 and other brands, and hot rolling uses HR30 HR40 HR60 and other brands containing heat-resistant components.

2. What are your advantages?

Our rollers have been verified by the market for many years and have a good reputation. We are direct manufacturers and can provide the lowest price.

3. What technical support do you provide?

We can customize and recommend the most suitable rollers according to your machine