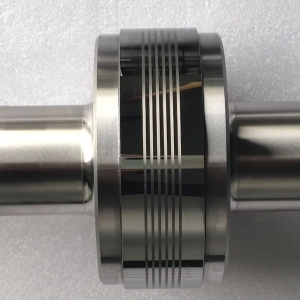

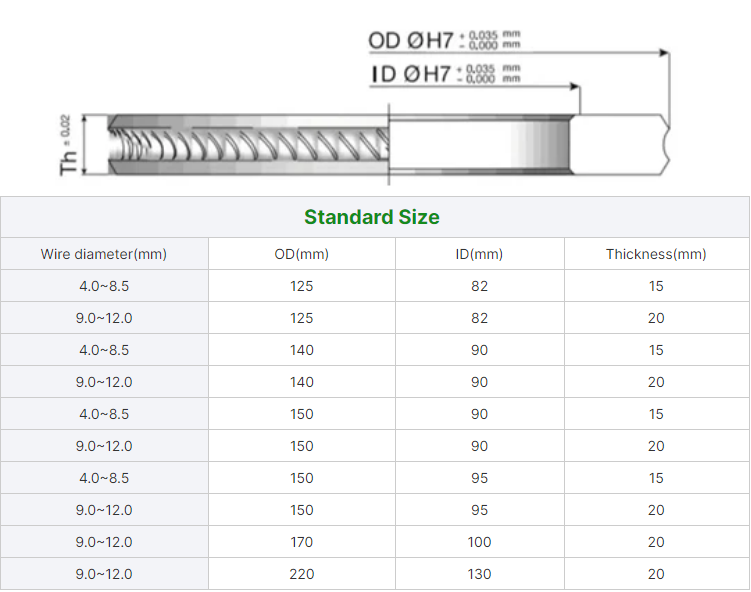

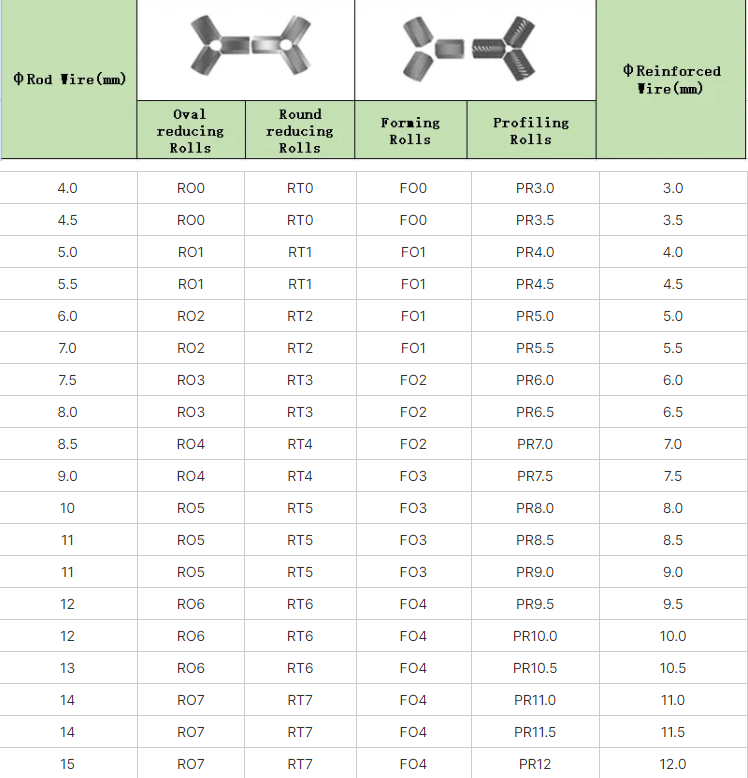

Tungsten Carbide mill rolls are used in the manufacturing of mill rolls & wire flattening

the availability of comprehensive supporting services further enhances the value of tungsten carbide roller rings for steel bar manufacturers. From technical assistance to maintenance and refurbishment, suppliers of these roller rings offer a range of services to ensure the optimal performance and longevity of the products. This comprehensive support underscores the commitment to customer satisfaction and long-term partnerships in the steel bar industry.

Choosing us for your tungsten carbide cold roll needs means gaining access to comprehensive support and expertise. Our team is dedicated to providing technical assistance, maintenance guidance, and troubleshooting support to ensure that our customers get the most out of our rolls. Whether it's optimizing roll performance, addressing operational challenges, or exploring new opportunities for improvement, we are committed to being a reliable partner every step of the way.

1. What are the main advantages of choosing your company as a supplier?

We can supply the best quality products, provide one-to-one service, and the lowest price.

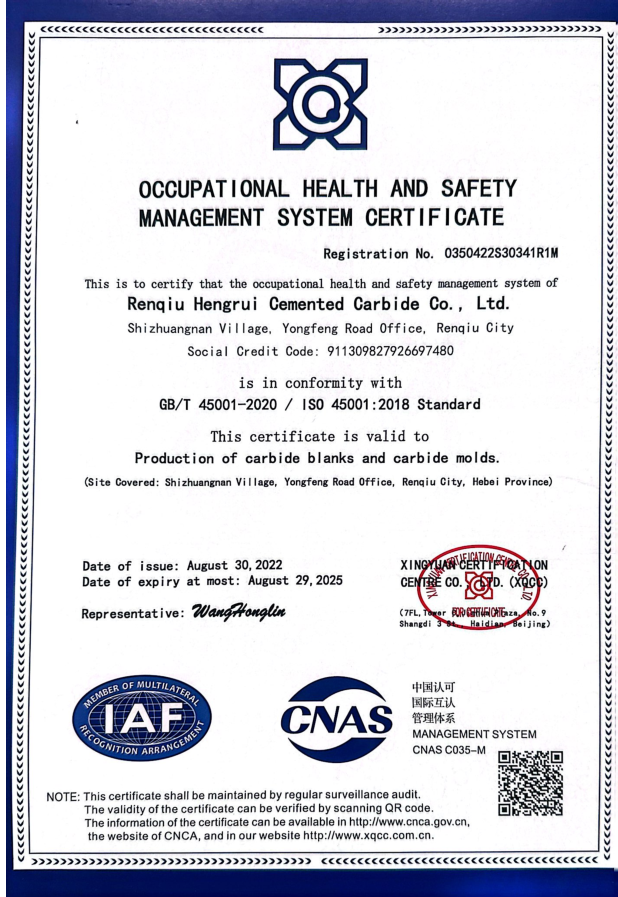

3. How does your company ensure the quality and reliability of its tungsten carbide rollers?

Yes, we have 30+ years of production experience and market experience. Combined with the market, we supply tungsten carbide rollers that best suit market needs.

4. Can you provide examples of successful projects or cooperation with your company?

Yes, our products are sold in Europe, Africa, South America and China.

5. How is your company different from other tungsten carbide roller suppliers in the market?

We provide inspection reports. In addition to strict size inspections, the products will undergo 11 physical tests such as spectral testing, hardness testing, bending strength, etc. before leaving the factory. Only after passing the inspections can they be used.