TC pellets cemented carbide cold heading dies GT55 CT95 carbide pallets

HR carbide is engaged in the manufacture of tungsten steel molds, with 20 years of experience and strong technical force. It can be customized according to customer requirements and has a complete range of molds. Tungsten steel molds are finely processed, with complete specifications, preferential prices, and guaranteed after-sales service. The physical and mechanical properties of tungsten carbide cold heading molds of different grades of cemented carbide are not consistent. When purchasing, you must carefully choose according to the use conditions, use environment, use purpose and requirements. If you have any questions about cemented carbide materials, please contact us and our professional alloy technicians will give you detailed answers.

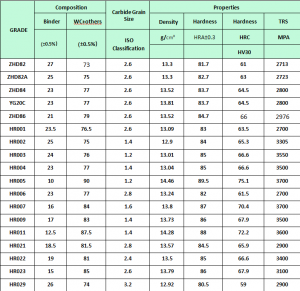

Analyze the ingredient list of tungsten carbide cold heading products, deeply analyze the key components of the products, analyze the differences in ingredients, analyze the main components/specified components, etc.

Analyze the formula of the samples and restore the formula list

Analyze the content of a certain substance in the product and the corresponding test method, provide key monomer information for the product, guide the selection of raw materials, and optimize product quality.

We understand that every project is unique, and we offer customization options to meet your specific requirements. Whether you need a standard carbide mold or a custom-designed solution, we have the capabilities to fulfill your needs.

R&D innovation: technical support for R&D, recommended production processes, helping enterprises to accelerate R&D, enhance core competitiveness, and accelerate industrial upgrading

Quality upgrade: product raw material testing and quality control, improve performance, promote technological innovation, improve product quality, and meet safety monitoring

Process improvement: locate the cause of product defects, quickly solve problems, help customers seize market opportunities, and deliver products quickly.

We can send international express such as DHL, FedEx, UPS, SF Express, etc. We can also choose lower-cost shipping methods such as sea transportation and air transportation.

1. What is tungsten carbide and why is it used in mold manufacturing?

Tungsten carbide is a composite material made of tungsten and carbon. It is widely used in mold manufacturing due to its exceptional hardness, wear resistance, and high temperature tolerance, making it ideal for producing high-quality and durable molds.

2. How can a tungsten carbide mold solve usage problems?

Tungsten carbide molds are known for their precision and durability, which allows them to effectively address common usage problems such as wear and tear, deformation, and poor mold quality. Their superior performance ensures consistent and reliable mold usage.

3. Can tungsten carbide molds be customized to specific requirements?

Yes, as an experienced tungsten carbide mold manufacturer, we have the capability to customize molds according to specific requirements. Whether it's a unique design, size, or material composition, we can tailor the molds to meet the exact needs of our customers.

4. What sets your company apart in terms of tungsten carbide mold production?

With 18 years of production experience, our company has developed a deep understanding of tungsten carbide mold manufacturing. We combine our expertise with advanced technology to deliver high-quality molds that excel in performance and longevity, setting us apart from other manufacturers.

5. What industries can benefit from using tungsten carbide molds?

Various industries, including automotive, aerospace, electronics, and manufacturing, can benefit from using tungsten carbide molds. These molds are suitable for producing a wide range of components and products that require precision, durability, and resistance to harsh operating conditions.