Supply ODM Yg6 YG8 YG10 YG15 Tungsten Carbide brazing flakes

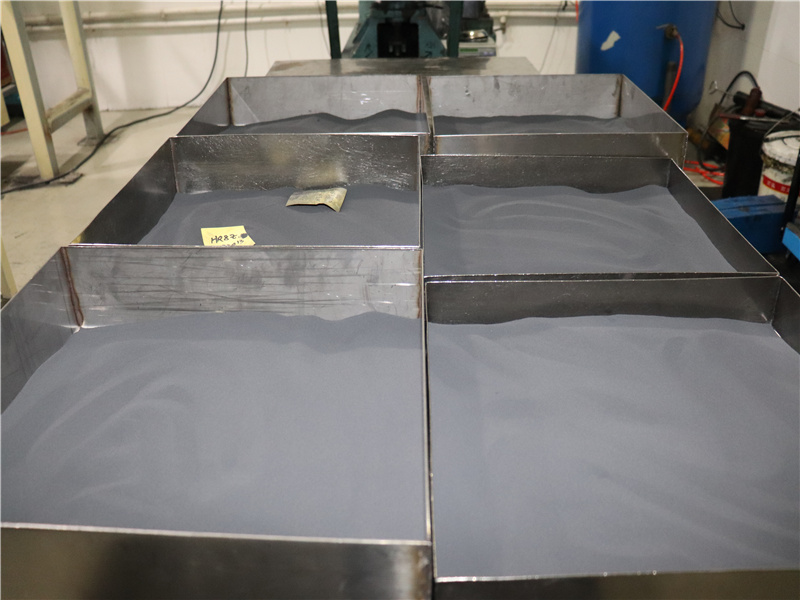

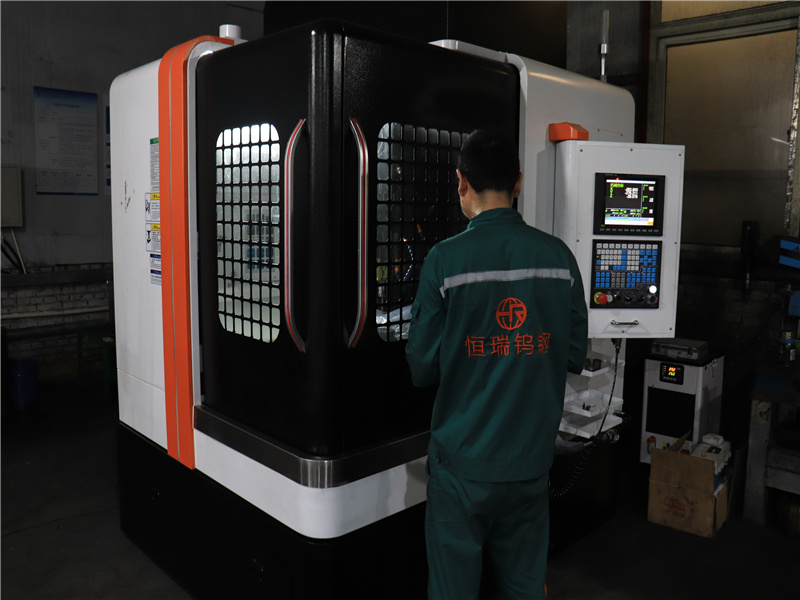

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Custom Manufactured Tungsten Carbide Parts, Carbide Bushing, Carbide Wear-parts, and More. Free Proofing, On-time Delivery, Excellent customer service, Strong Technical Team.

Tungsten Carbide roll ring is a kind of tool material which consist of tungsten carbide and cobalt with high hardness and wear resistance.To take advantage of high wear resistance,long life and high effciency of cemented carbide roll rings.

The cemented carbide cold heading die is required to have good impact toughness, fracture toughness, fatigue strength, bending strength, and wear resistance.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment,while,If there is soecific requests on delivery time.We can make change according to clients’ request,so a shorter delivery time is absolutely available.

Q1: Why did you choose us?

A1: We are the factory, we offer our clients are all wholesale price and best quality.

Q2: Do you provide free samples?

A2: Yes, we welcome all clients to get free samples for testing under the condition of freight paid by customer.

|

ur advantages

|

1.High quality

|

|

2.Reasonable price

|

|

|

3.On time delivery

|

|

|

4.Good After-sale service

|

|

|

5.Strict quality control

|

|

|

6.All the mold are automotic.

|

|

|

We will offer you

|

1.In-time response on letters, telephone calls or fax

|

|

2.In-time supply the quotation and mold designs

|

|

|

3.In-time communication on the technical points

|

|

|

4.In-time sending pictures for the mold machining progress and mold finishing

schedule |

|

|

5.In-time mold test and sample delivery

|

|

|

6.In-time mold delivery.

|