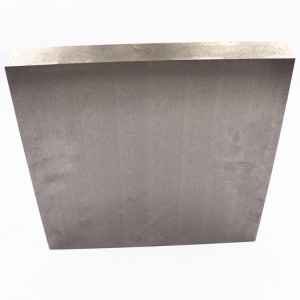

100% Virgin Material Hip Tungsten Carbide Blocks Tungsten Carbide Parts Carbide Plate

Precision grinding high-performance carbide plate tungsten steel plate product introduction

1. The purity of raw materials reaches more than 99.95%, the impurity content is low, and the physical properties of the board are more stable;

2. Using spray drying technology, the material is protected by high-purity ammonia under fully sealed conditions, which effectively reduces the possibility of oxygenation during the preparation process of the mixture. The purity is better and the material is not easy to become dirty;

3. The density of the board is uniform: it is pressed with a 300Mpa isostatic press, which effectively eliminates the occurrence of pressing defects, and the density of the board blank is more uniform: 4. The density of the board is excellent, and the strength and hardness indicators meet the standards: low-pressure sintering technology is used to make the board Internal pores are effectively eliminated, and the quality

more stable.

The internal metallographic structure of the plate can be improved and the internal stress can be greatly reduced, effectively avoiding the possibility of cracks in the plate during the cutting and forming process. 5. Use cryogenic treatment technology;

[Application range of carbide plate and tungsten steel plate]:

Suitable for making cast iron rolls and high-nickel-chromium roll dressing and shaping knives;

Suitable for making unloading plates, stamping dies, punch dies, electronic progressive dies and other stamping dies, etc.

Non-standard customization, special customization. Pictures and online quotations are for reference only. Prices may vary depending on specific specifications, raw materials, costs, and order quantity.

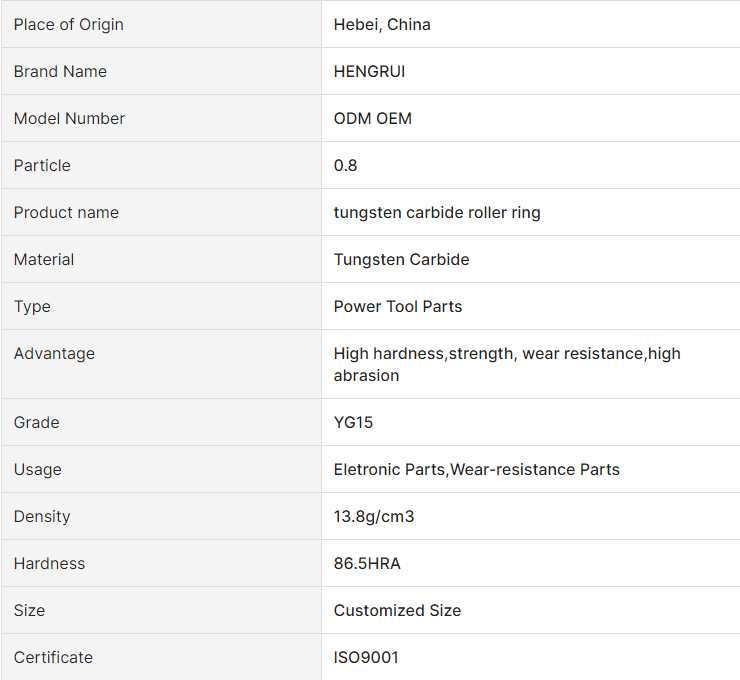

Various Grades for Options:

| Tungsten Carbide Cold Forging/heading Dies | |||||

| Grades | Density | T.R.S | Hardness | Performance & application recommended | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | |

| YG15 | 14 | ≥3400 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, forging tools under large stress. | |

| YG20 | 13.5 | ≥3800 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. | |

| YG15C | 14 | ≥4000 | 86.5 | For oil cone drill bits,cut medium soft and hard rocks;debarking and cutting of frozen wood,soft wood and original wood. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging dies. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Dies for wear resistant or impact resistant application. | |

| YG22C | 13.3 | ≥4000 | 83 | Nut forming dies and high impact resistance forging dies. | |

| YG25C | 13.1 | ≥4250 | 82.5 | Stainless bolt header dies and rollers. | |

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

All the produces must be inspectedstrictly with the ultrasonic and onlythose haven't any harm such aspore can be shipped out.Highdensity,high wear&impactresistance,which lead them a longlifetime.

We have a powerful and educated team including: Management team 10 persons,Research team 5 persons,77 Experienced workers.10 Sales managers.

We adopt 7S system management-Seiri, Seiton,Seiso, Seiketsu,Shitsuke, Safety,Speed,Saving.Every products series is in charge of one professional sales engineer

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.