Industry News

-

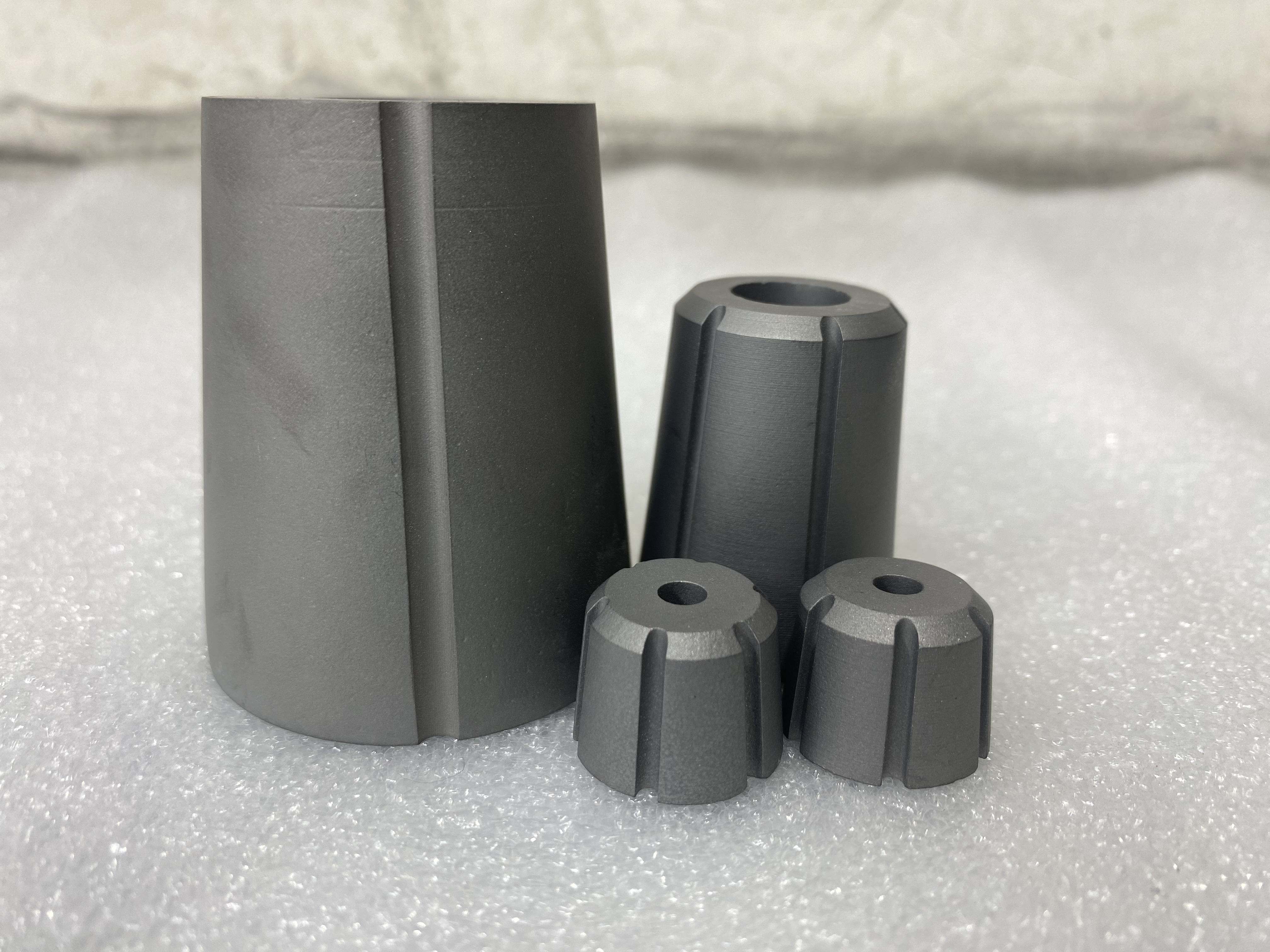

Cemented carbide sintering process flow

The sintering of cemented carbide is liquid phase sintering, that is, it is carried out under the condition that the bonding phase is in liquid phase. The compact is heated to 1350C-1600C in a vacuum furnace. The linear shrinkage of the compact during sintering is about 18%, and the volume shrink...Read more -

Carbide forming process

The mainly includes: (1) Dissolving rubber or paraffin with gasoline, precipitating and filtering, and preparing molding agents; (2) Conducting pressure tests on new molds and specific forms of carbide products to determine compression molding parameters; (3) Operating presses , put the quantit...Read more -

What is tungsten carbide powder

Tungsten carbide powder (WC) is the main raw material for the production of cemented carbide, with the chemical formula WC. The full name is tungsten carbide powder. It is a black hexagonal crystal with a metallic luster and a hardness similar to diamond. It is a good conductor of electricity and...Read more -

Analysis of the shortcomings of cemented carbide

1. Easy to expand due to heat Cemented carbide is prone to thermal expansion problems during high temperature and cooling processes. The main reason is that the thermal expansion coefficient of cemented carbide is larger than that of ordinary metals. This means that in high temperature environmen...Read more -

The disadvantages of cemented carbide mainly include the following points:

Hot cracking defects: Carbide is prone to hot cracking at high temperatures. This is mainly because cobalt may react with carbides at high temperatures to form harmful phases, thereby reducing the toughness and reliability of the material Porosity defects: Carbide contains pores. These defects a...Read more -

The difference between YG15 YG20 YG8 Grade

1. Which one has better impact resistance, yg+15 or yg+20: YG15 and YG20 are two grades of cemented carbide. There is no good or bad, it just depends on what occasion you use it. YG15 contains about 15% cobalt, has higher hardness than YG20, and lower strength than YG20. 2. Which one is easier t...Read more -

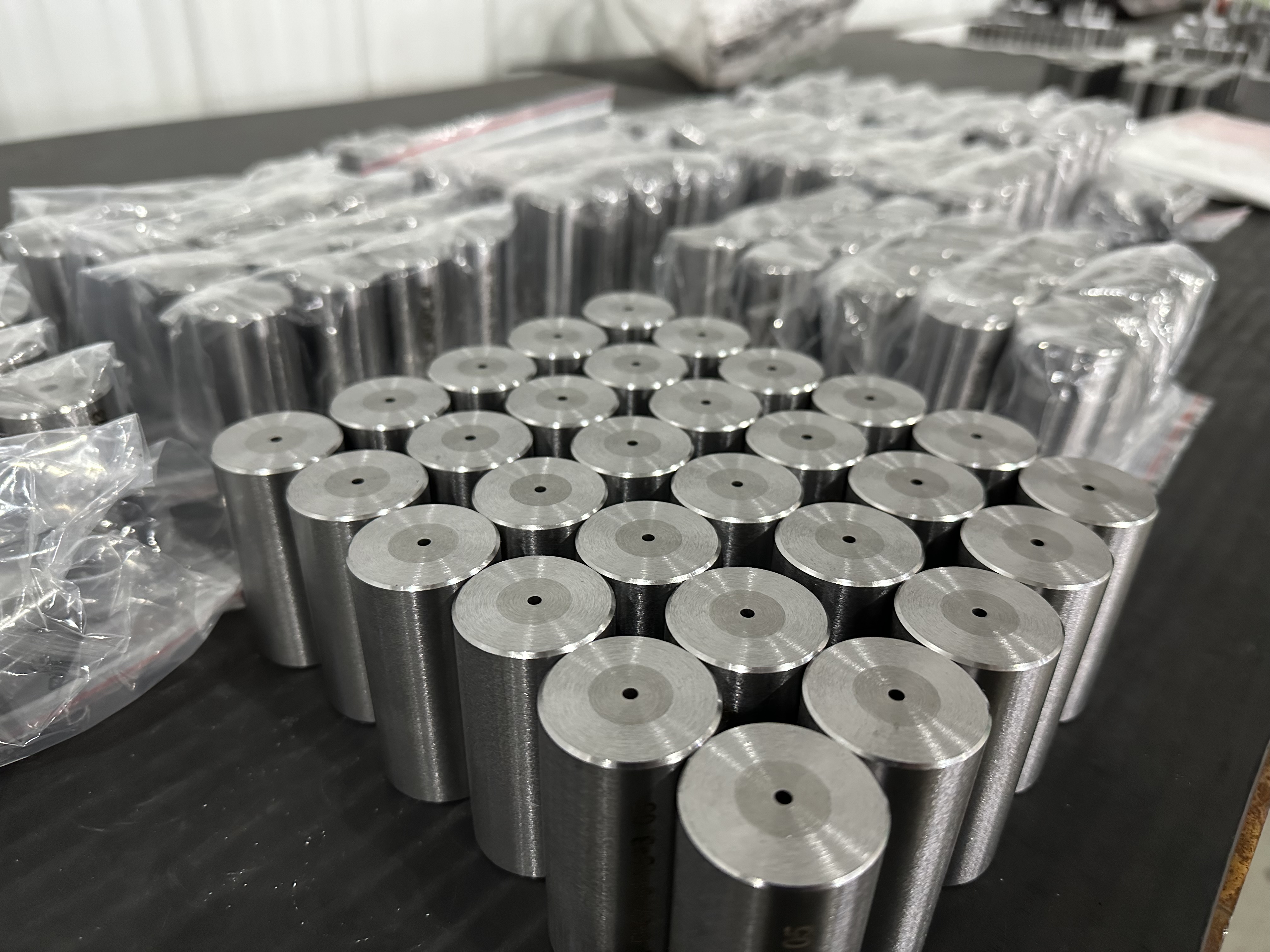

Production process of cemented carbide mold

Every step in the production process of cemented carbide molds is critical and directly affects the quality and performance of cemented carbide molds after production. What is the production process of cemented carbide molds? The technical engineers of Renqiu Hengrui Cemented Carbide Co., Ltd. ha...Read more -

What are the differences between domestic cemented carbide and imported alloys?

1. Different production processes There are certain differences in the production processes between domestic cemented carbide and imported alloys. The imported alloy production process is more advanced, the formula used is more precise, and the product quality is more stable and reliable. The pro...Read more -

The difference between carbide strips and tungsten steel strips

The colors of carbide strips and tungsten steel strips are different The color of cemented carbide strips is usually lighter than that of tungsten steel strips, and the colors are mainly gray, silver, gold, and black. This is because the carbide strip contains more metal elements, which makes it ...Read more -

Effect of cobalt content in cemented carbide on material properties

The cobalt content of cemented carbide has a significant impact on the properties of the material, including hardness, toughness, wear resistance and impact resistance. The following is the relationship between the cobalt content of cemented carbide and its performance 1.Hardness Cemented carbid...Read more -

The impact of cemented carbide carbon content control on quality

The carbon content in cemented carbide was studied using the vacuum sintering method. The analysis pointed out that the total carbon content in the raw materials plays a decisive role in the carbon content of the alloy. In addition, the hard particles in the pressed powder are formed during the p...Read more -

Mold manufacturing installation and commissioning

The manufacturing of cemented carbide molds needs to be based on specific standards and processes, including material selection, processing technology, heat treatment technology, precision grinding and other aspects. Scientific and standardized manufacturing standards must be followed during the ...Read more