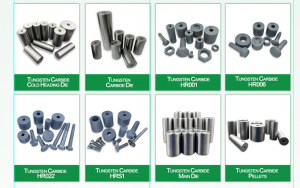

Benefits of using carbide cold heading dies

In the cold heading process, the choice of mold plays a vital role in determining the quality and efficiency of production. Carbide cold heading dies are popular in the manufacturing industry due to their many advantages. So, why use carbide cold heading molds?

First, carbide cold heading dies are known for their exceptional durability. The use of carbide, a composite material composed of carbon and other elements, makes these molds highly wear-resistant. This means they can withstand the high pressure and repeated impacts of the cold heading process, extending mold life and reducing downtime for changing molds.

In addition to durability, carbide cold heading dies offer excellent performance. The hardness and toughness of carbide allow for precise and consistent shaping of metal parts, resulting in high-quality finished products. This level of performance is particularly important in industries such as automotive and construction, where part integrity is critical.

In addition, using tungsten carbide cold heading molds can save costs in the long run. While the initial investment in carbide molds may be higher than traditional steel molds, they last longer and reduce the need for frequent replacements, making them a cost-effective option for manufacturers in the long run. This in turn helps increase productivity and overall efficiency in the production process.

Another advantage of carbide GT55 cold heading dies is their versatility. They are available in a variety of materials, including steel, aluminum and copper, making them suitable for a variety of manufacturing applications. This versatility enables manufacturers to streamline their mold inventory and production processes, ultimately saving time and resources.

In summary, using carbide cold heading pellets dies offers many advantages, including durability, performance, cost savings, and versatility. As the manufacturing industry continues to demand high quality and efficient production processes, carbide cold heading molds have proven to be a valuable investment for manufacturers looking to enhance their cold heading operations. By using gt55 carbide cold heading dies, manufacturers can increase productivity, reduce downtime, and ultimately gain a competitive advantage in their respective industries.

https://www.ihrcarbide.com/tungsten-carbide-cold-heading-die/

HR CARBIDE

E-mail: hengrui@hrcarbide.cn

Post time: May-25-2024