Tungsten carbide rolls: a key component in metal forming

Carbide rolls are an important part of the metal forming industry and play a vital role in the production of various metal products. These rolls are known for their exceptional hardness, wear resistance and high temperature strength, making them ideal for demanding metal forming applications. Therefore, the demand for high-quality carbide rolls is increasing, prompting many companies to seek reliable suppliers. In Turkey, more and more carbide roll suppliers are emerging to meet the needs of local and international markets, offering a wide range of products and services to support the metal forming industry.

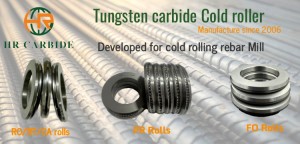

When purchasing carbide rolls in Turkey, it is essential to work with reputable suppliers who can provide high-quality products that meet industry standards. These suppliers offer a variety of tungsten carbide rolls designed for a variety of metal forming processes, including wire and bar drawing, tube production, and hot and cold rolling. In addition, they can provide customized solutions to meet specific customer requirements, ensuring that the rolls can meet the unique needs of different metal forming applications.

One of the main advantages of sourcing carbide rolls from Turkish suppliers is the country’s strategic location, providing easy access to key markets in Europe, the Middle East and Asia. This geographical advantage enables Turkish suppliers to efficiently serve a global customer base, offering competitive pricing, reliable delivery and excellent customer support. In addition, many suppliers in Turkey are committed to continuous innovation and investment in advanced manufacturing technology to ensure that their carbide rolls are produced with the highest precision and quality.

In addition to supplying standard tungsten carbide rolls, many Turkish suppliers offer value-added services such as roll refurbishment, regrinding and repair. These services are critical to extending the life of your carbide rolls, reducing maintenance costs, and maximizing the overall efficiency of your metal forming operation. By partnering with a supplier that offers comprehensive roll management solutions, metal forming companies can optimize their production processes and minimize downtime, ultimately increasing their market competitiveness.

Overall, the continued growth of Turkey’s tungsten carbide roll suppliers reflects the country’s commitment to supporting the metal forming industry with high-quality products and services. As global demand for carbide rolls continues to grow, Turkish suppliers are well-positioned to play an important role in meeting the needs of global metal forming companies. By leveraging their expertise, technical capabilities and customer-centric approach, these suppliers are poised to contribute to the advancement and sustainability of the metal forming industry, driving innovation and excellence in the production of various metal products.

Post time: Sep-10-2024