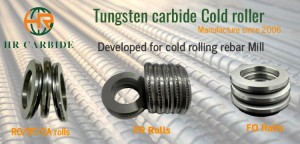

Tungsten carbide rolls are widely used in various industries due to their exceptional hardness, wear resistance, and high-temperature strength. These rolls are made from a combination of tungsten and carbon, resulting in a material that is ideal for demanding applications. Let’s explore the versatile application of various tungsten carbide rolls across different industries.

In the metalworking industry, tungsten carbide rolls are commonly used in the production of wire, rod, and bar mills. These rolls are essential for achieving precise and consistent shaping of metal products. Their superior wear resistance allows for extended use, reducing the need for frequent replacements and maintenance.

In the manufacturing of seamless tubes and pipes, tungsten carbide cold rolls play a crucial role in the production process. The rolls are used in the piercing, elongating, and sizing of the metal, ensuring the production of high-quality and uniform tubes. Their ability to withstand high temperatures and heavy loads makes them an ideal choice for this application.

Tungsten carbide rolls are also utilized in the production of flat products such as sheets and strips. Their exceptional hardness and resistance to deformation make them well-suited for rolling mills, where they are used to shape and refine metal into the desired thickness and surface finish.

In the textile industry, tungsten carbide PR rolls find application in the production of synthetic fibers and yarns. These rolls are used in the drawing and spinning processes, where they help in maintaining consistent tension and reducing friction, resulting in improved product quality and production efficiency.

Furthermore, tungsten carbide rolls are employed in the manufacturing of paper and plastic products. They are used in calendering and embossing processes, where they contribute to achieving precise and uniform surface textures on the materials.

In conclusion, the application of various Tungsten carbide cold forming rolls spans across a wide range of industries, including metalworking, tube and pipe production, flat product manufacturing, textile, and paper and plastic production. Their exceptional properties make them indispensable for achieving high precision, durability, and efficiency in various manufacturing processes. As technology continues to advance, the versatility and demand for tungsten carbide rolls are expected to grow, further solidifying their position as a critical component in industrial production.

https://www.ihrcarbide.com/

E-mail: hengrui@hrcarbide.cn

Mia Wang

Post time: Apr-17-2024