News

-

What are the advantages of carbide molds?

1. High hardness The main components of cemented carbide molds are tungsten carbide and cobalt. This material has a very high hardness, usually in the range of 90 to 95 HRA, and some can even reach 97 HRA. This means that carbide molds can be efficiently cut and processed with many materials, su...Read more -

Happy International Labor Day

May is the season of youth. On the occasion of the May Day International Labor Day, I would like to extend my holiday congratulations and sincere condolences to everyone, and wish you all a happy holiday! All employees of Renqiu Hengrui Cemented Carbide are of the same mind as the company, striv...Read more -

Effect of size on the use of tungsten carbide rolls

The size of tungsten carbide rollers refers to their diameter, length, and overall dimensions. The size of the rollers has a significant impact on their use in different industrial processes. One of the key factors affected by the size of tungsten carbide rollers is their load-bearing capacity. L...Read more -

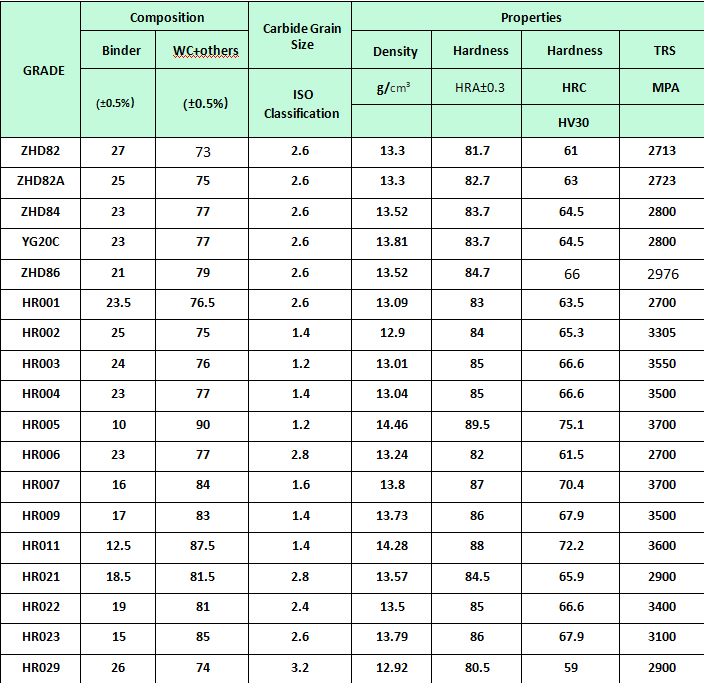

What are the commonly used cemented carbides? What are their performance characteristics and uses?

Cemented carbide is a composite material composed of metal powder, binder and hard phase. The hard phase is usually carbide, nitride, boride, etc., which has high hardness and good wear resistance. The binder plays a role in connecting the hard phase. Commonly used binders include cobalt, nickel ...Read more -

The price of tungsten has increased by nearly 13.5% in this round, and the price of tungsten carbide products is about to rise.

This round of tungsten price increases began in mid-November 2023. So far, the price of 65% black tungsten concentrate has increased by 13.45%, the price of ammonium paratungstate has increased by 11.24%, the price of tungsten powder has increased by 10.45%, the price of tungsten carbide powder h...Read more -

What is the difference between carbide grade YG8 and YG20

1. The main difference between the two is the cobalt content, one is 8% and the other is 20%. There should be no difference in appearance. If one of them is magnetic, the other one must also be magnetic, so magnets cannot tell the difference. Without destroying the original, I have a way to tell ...Read more -

HR CARBIDE- What are the surface damages of hot mill rolls?

Understanding Surface Damage on Hot Rollers Hot rolls play a vital role in the metal processing industry as they are responsible for shaping metal into various products. However, continued exposure to high temperatures and heavy loads can cause surface damage to the rollers, affecting their perfo...Read more -

How to reasonably choose carbide models

Carbide, commonly known as cemented carbide material, is a new material that has been widely used in various industries in recent years. It has the characteristics of high hardness, good wear resistance, corrosion resistance, etc., so it can be widely used in manufacturing various tools, Molds, m...Read more -

The Versatile Application of Various Tungsten Carbide Rolls-HR CARBIDE

Tungsten carbide rolls are widely used in various industries due to their exceptional hardness, wear resistance, and high-temperature strength. These rolls are made from a combination of tungsten and carbon, resulting in a material that is ideal for demanding applications. Let’s explore the versa...Read more -

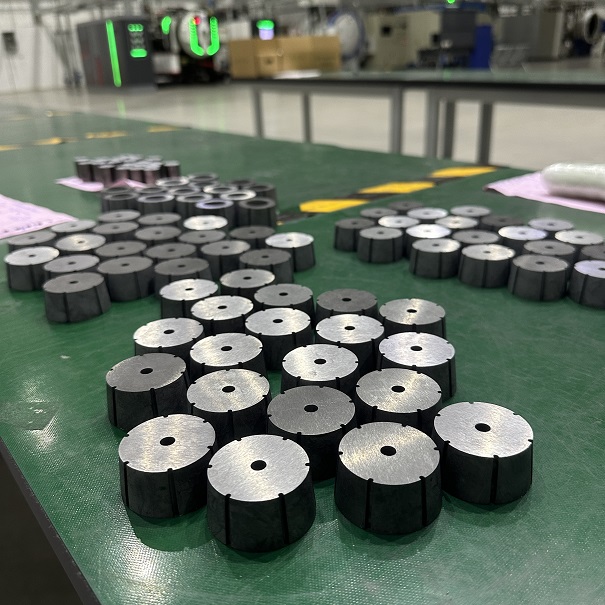

Our Tungsten Carbide Heading Dies and Punches

Usually, the heading dies has the structure of the WC-Co (Carbide) with the dies steel which reinforcing the WC-Co(Carbide).Since the WC-Co (Carbide) is bristtle materials and very expensive, all dies might not be made of the WC-Co (Carbide).We produce the die material by making a hole to the die...Read more -

What’s about the Tungsten Carbide Heading Dies?

The WC-Co (Carbide) is the generic name for certain metal that is combined with a tungsten carbide (WC) and a cobalt (Co) which is a binder and sinters at a high temperature and produced. Generally, it is considered to have the hardness next to the diamond, but it can be changed the ratio of WC...Read more -

What are the advantages of using cemented carbide?

Because many parts and other processing require the use of cemented carbide, and it can also be used as mold steel to ensure wear resistance and accuracy of parts processing, so it is still very popular. Moreover, such an alloy has strong stability and can ensure good dimensions even for long-ter...Read more