News

-

History of rolls

Roll variety and manufacturing process with the progress of metallurgical technology and the evolution of steel rolling equipment and continuous development. In the middle of the 18th century, Britain mastered the production technology of chilled cast iron rolls for rolling steel plates, and in t...Read more -

Main properties of cemented carbide rolls

The main properties of tungsten carbide to be considered in selecting tungsten carbide rolls are as follows: Resistance to thermal cracking Usually for rough rolls to strength, resistance to thermal cracking as the main requirements; small 20-roll mill working rolls weigh only about 100 grams, wh...Read more -

Classification and application of cemented carbide rolls

There are many ways to classify rolls, mainly: (1) strip rolls, section rolls, wire rod rolls, etc. according to the type of products; (2) tungsten carbide rolls, rough rolls, finish rolls, etc. according to the position of rolls in the mill series; (3) scale breaking rolls, perforating rolls, le...Read more -

Implementation of workshop standards to ensure product quality

In view of the nature and special nature of the work of the tungsten carbide alloy pressing workshop, the company has put forward specific requirements for the staff workshop as follows: 1. Equipment requirements: the workshop should be well equipped with advanced technology to meet the needs of ...Read more -

Cemented carbide plate

Cemented carbide plate has high hardness, good wear resistance, strength and toughness, heat resistance, corrosion resistance, and a series of excellent properties, especially its high hardness and wear resistance, even if the temperature at 500 degrees also remains basically unchanged. Character...Read more -

Adapting the working model to the current market

This morning at 7:50 in the tungsten carbide sintering workshop held by the scientific research department, the director of the production management department, sintering workshop employees to participate in the work mode adjustment meeting. Before the meeting, Mr. Liu combined with the rectifi...Read more -

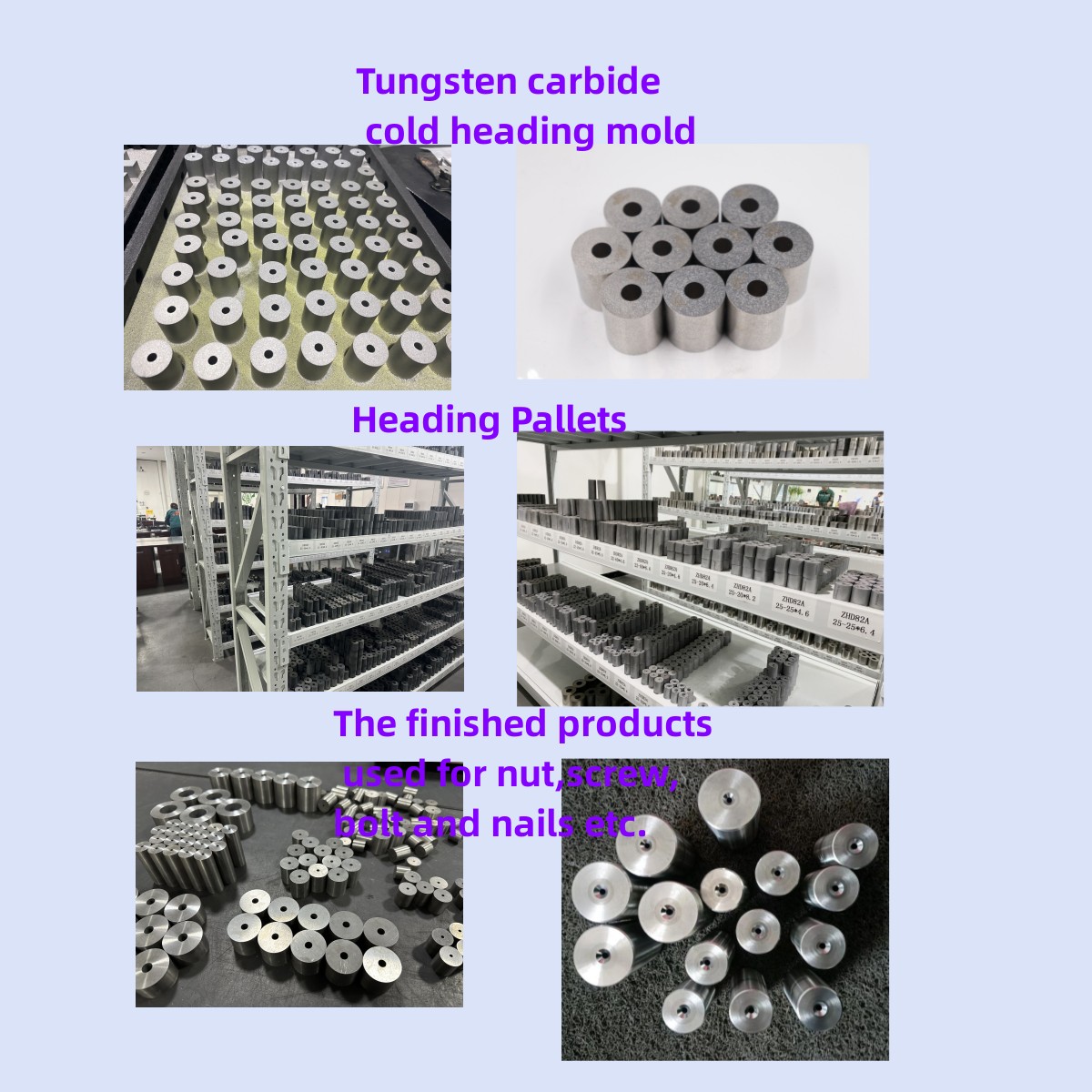

Do you know what is the cold heading?

Yes, cold heading is a mechanical processing process, also known as cold working, which is used to make steel bars, rebars, wires, rivets, etc. The head shape of the screw during the production process is usually completed by a heading machine. The specific process is as follows: 1. Cut to lengt...Read more -

Application of carbide cold heading dies

Tungsten carbide cold heading die are specialized tools used in the manufacturing process of fasteners, such as screws, bolts, and rivets. These dies are made of carbide, a hard and durable material that can withstand the high pressure and stress of the cold heading process. The cold heading proc...Read more -

Tungsten carbide Application and Synthesis Method

Physical and chemical properties of tungsten carbide is a dark gray crystalline powder. Relative density is 15.6(18/4℃), melting point is 2600℃, boiling point is 6000℃, Mohs hardness is 9. Tungsten carbide is insoluble in water, hydrochloric acid or sulfuric acid, but soluble in the mixture of ni...Read more -

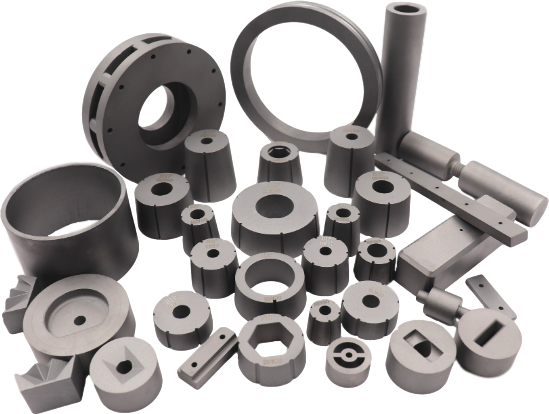

Which fields are tungsten carbide molds applied to use?

Cemented carbide cold heading dies play a very important role in the process of manufacturing cold heading parts. Through carbide cold heading dies, metal materials can be deformed into various shapes, such as bolts, nuts, screws, pins, chains, etc. Tungsten carbide cold heading dies are usually ...Read more -

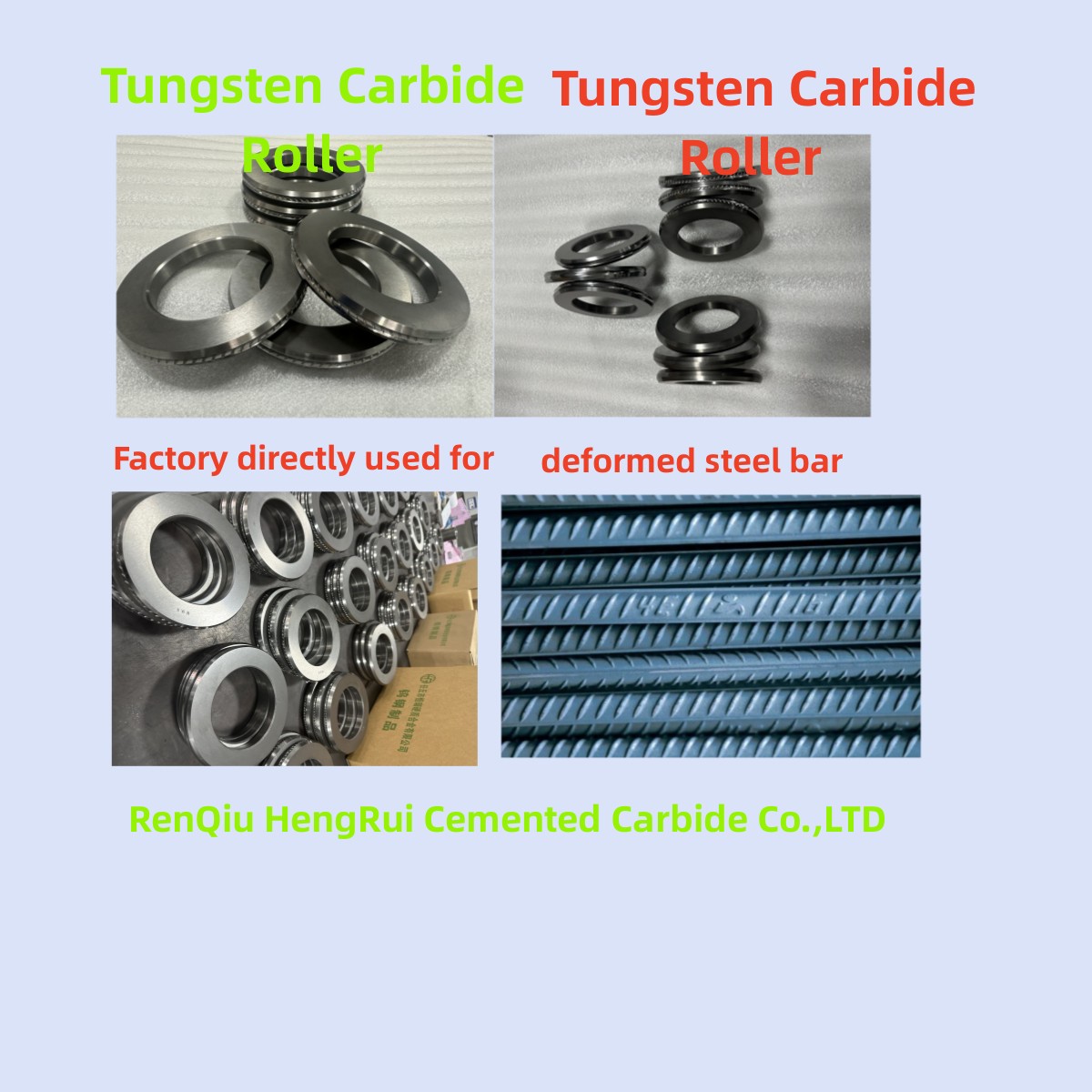

How deformed steel bar is produced? The deformed steel bar production lines!

Deformed steel bars, also known as reinforcing bars or rebars, are produced by carefully controlling the manufacturing process of hot-rolled steel wire rod. Here’s a general production process: 1. Steel wire rod is produced through a hot-rolling process that compresses the steel at high tem...Read more -

Sintering temperature of tungsten carbide cold heading die

Cold heading dies are molds for cold heading processing, usually made of high-speed steel, alloy tool steel, hard alloy and other materials. Cold heading is a metal forming process in which the metal rod material is pressed and extruded through multiple dies to achieve a certain shape and size p...Read more