News

-

Applications of tungsten carbide bushing

Tungsten steel bushings are mainly used in stamping aspect and drawing aspect. Carbide is widely used as tool material, such as turning tool, milling tool, planer, drill, boring tool, etc. It is used to cut cast iron, non-ferrous metal, plastic, chemical fiber, graphite, glass, stone and common s...Read more -

What are the factors that affect the sintering densification process of cemented carbide

Cemented carbide is a powder metallurgical product made from carbide (wc, tic) micron-sized powder of high hardness refractory metals with cobalt (co) or nickel (ni) and molybdenum (mo) as the binder, sintered in a vacuum furnace or hydrogen reduction furnace. When manufacturing cemented carbide...Read more -

What effect does the grain size of a metal have on the metal?

When a metal crystallizes, it is a polycrystal composed of many grains. The grain size can be expressed by the number of grains in a unit volume. The higher the number, the smaller the grain size. The number of grains per unit cross section or the average diameter of the grains is often used for ...Read more -

What is the difference between high speed tool steel and carbide tools?

High-speed tool steel is still essentially tool steel, but with better heat resistance. Carbide is a super hard material made of tungsten carbide, titanium carbide and other materials. In terms of hardness and red-hardness, high-speed tool steel can’t catch up with them. Although the name i...Read more -

The future is come! Cemented carbide materials are transforming machinery manufacturing.

Yes, cemented carbide, as a super material, has played an increasingly important role in the machinery manufacturing industry. Its appearance and application have changed the limitations of traditional materials, and greatly improved the precision, wear resistance, corrosion resistance, compressi...Read more -

Why is Cemented Carbide a super material?

Cemented carbide is a super material with high strength, wear resistance, corrosion resistance, high temperature resistance, compression resistance and bending resistance. Has the following advantages: 1. High hardness and high strength. Cemented carbide is harder than ordinary metal materials a...Read more -

What are the factors that affect the sintering densification process of cemented carbide

The sintering of cemented carbide is liquid phase sintering, i.e. the re-bonding phase is in liquid phase. The pressed billets are heated to 1350°C-1600°C in a vacuum furnace. The linear shrinkage of the pressed billet during sintering is about 18% and the volume shrinkage is around 50%. The exac...Read more -

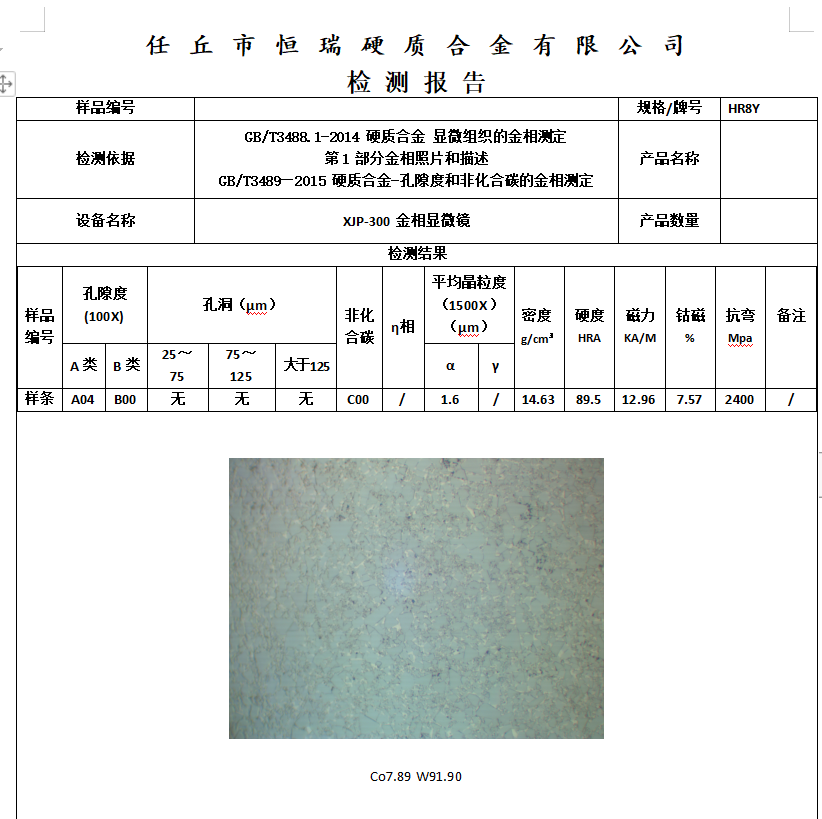

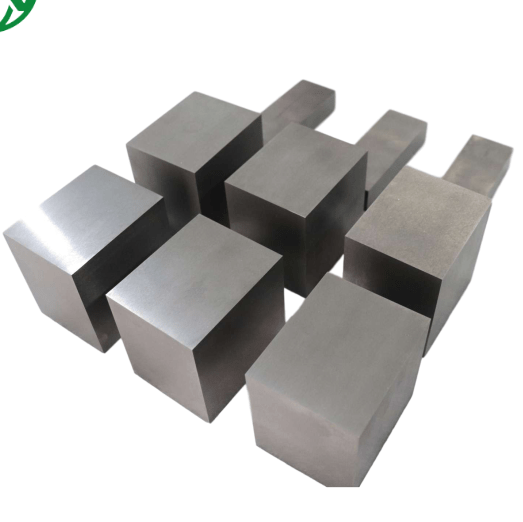

Cemented Carbide Plates

Tungsten carbide plate is one of the many materials of tungsten steel, using the cure method by making powder, ball milling, pressing, sintering, different uses of tungsten steel plate in the composition of WC and Co content is not the same, the use of a wide range of extremely good by hardness, ...Read more -

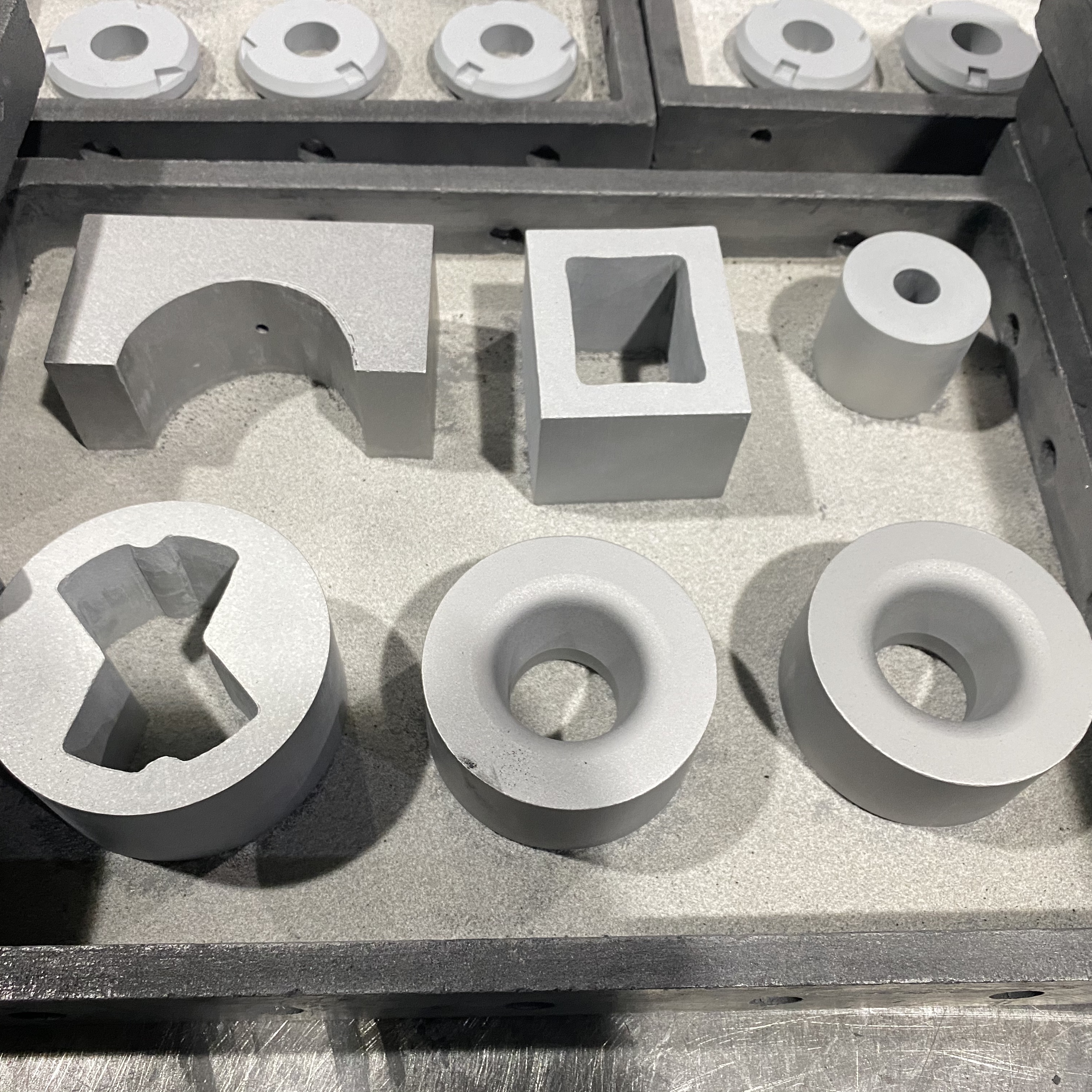

How are Cemented Carbide dies produced?

Each step in the production process of tungsten carbide tooling is critical and directly affects the quality and performance of the carbide tooling after production. What is the production process of Cemented Carbide Moulds? 1: raw materials do spray drying: mixture preparation in a fully closed...Read more -

Tungsten Carbide Pressing Process

Cemented carbide pressing is a hard and highly wear-resistant material made by mixing metal powder (usually tungsten-cobalt or tungsten-titanium carbon, etc.) with a certain amount of binder, and then pressing and sintering. Cemented carbide has the characteristics of excellent wear resistance, c...Read more -

Applications of tungsten carbide hammer

A carbide hammer is usually a tool consisting of a metal head and a wooden handle. The head is usually made of cemented carbide, because cemented carbide has high hardness, high wear resistance and high fracture resistance. This material is better able to withstand repeated impact and stress, giv...Read more -

Cemented carbide drawing dies

Tungsten carbide drawing dies are widely used in the mechanical performance testing of metal and non-metal materials, including: 1. Metal materials: Carbide tensile dies are suitable for testing the mechanical properties of various metal materials, such as steel, copper, aluminum, magnesium, tit...Read more