News

-

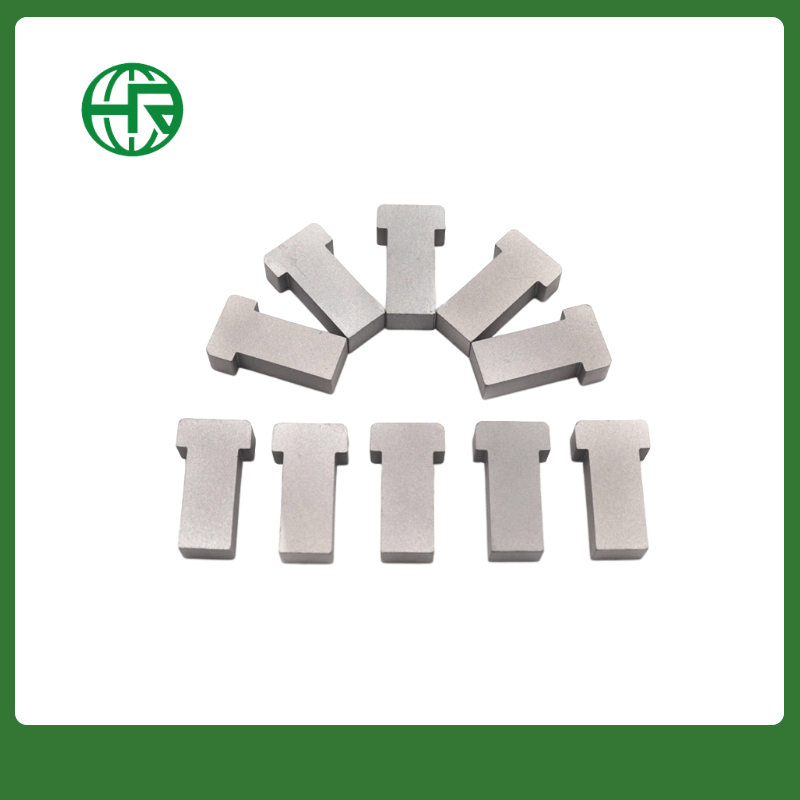

Use of tungsten carbide hexagonal bolts

Tungsten carbide hexagon bolt is a special hexagon bolt, which is made of tungsten carbide material. Tungsten carbide has extremely high hardness and wear resistance, so tungsten carbide hexagon bolts have higher strength and durability, and are suitable for some special working environme...Read more -

Tungsten carbide dies and fastener

Cemented carbide (also known as tungsten steel) is a hard material made of tungsten and metal powders such as cobalt or nickel after high-temperature sintering. It has the characteristics of high hardness, good wear resistance, strong corrosion resistance, etc., and is often used in the manufactu...Read more -

Carbide Tensile Stainless Steel

Cemented carbide refers to a composite material composed of metals (such as cobalt, nickel, etc.) and one or more non-metals (such as carbon, titanium, etc.), with high hardness and wear resistance. Stainless steel is an alloy composed of iron, chromium, nickel and other elements, which has corr...Read more -

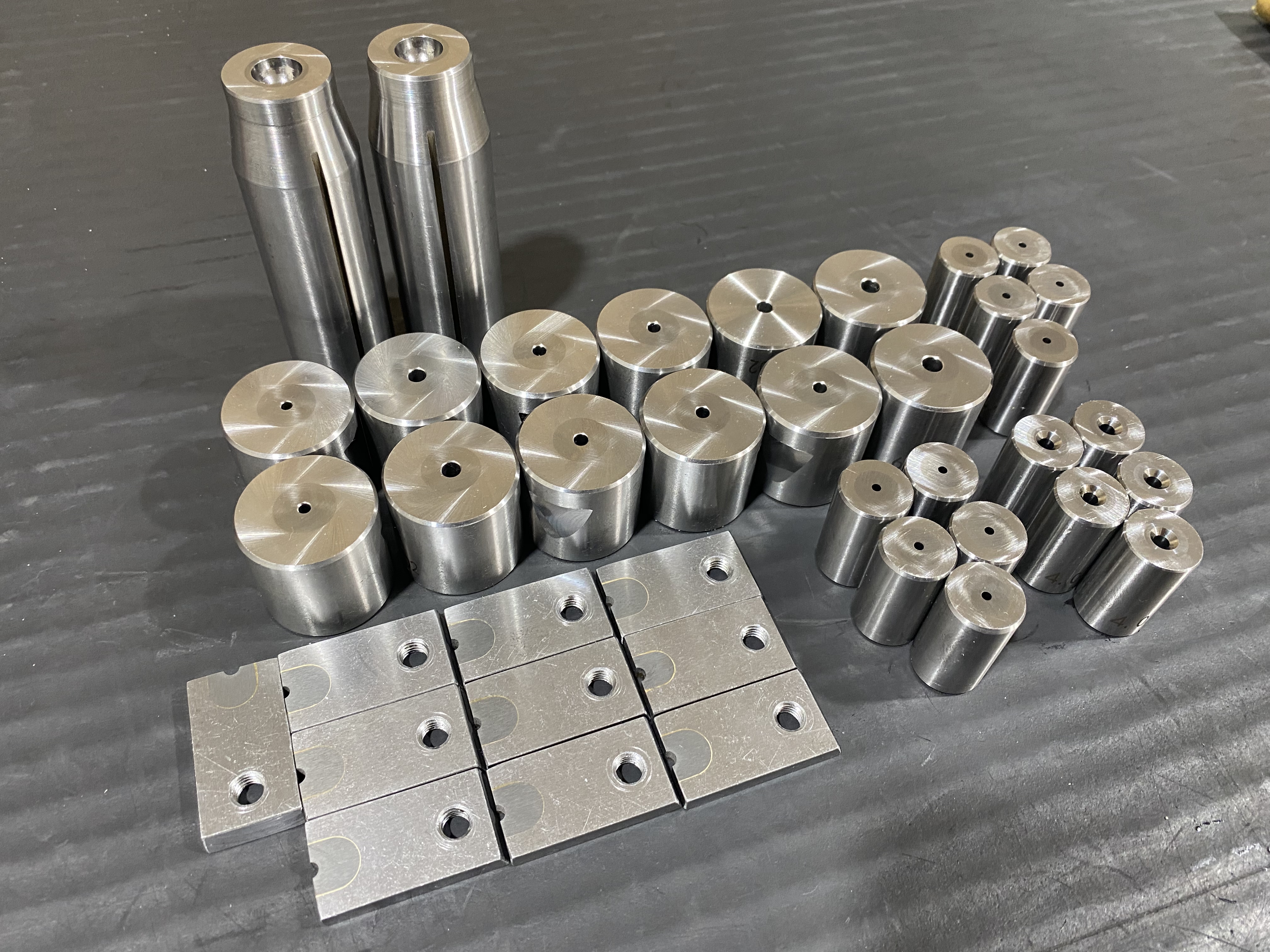

Cemented carbide fastener tooling

Carbide fastener mold refers to the mold used to manufacture carbide fasteners (such as screws, nuts, bolts, etc.). These molds are usually made of high-hardness carbide materials to ensure that the molds can withstand high pressure and friction, and have good wear resistance and corrosion resis...Read more -

Application of cemented carbide in cold heading machine

Cemented carbide has a wide range of applications in cold heading machines. The following are some major application areas: 1. Cold heading dies: Cemented carbide is widely used in the manufacture of cold heading machine dies, including dies and punches. Cemented carbide has high hardness, excel...Read more -

Tungsten carbide wire drawing dies

Carbide drawing die is a kind of die used for metal wire drawing. It is usually made of cemented carbide and is widely used because of its high hardness, wear resistance and corrosion resistance. Carbide drawing dies are usually used to make wire materials, such as steel wire, copper wire, alum...Read more -

Machining method of cemented carbide and machining equipment

Let’s start with the processing equipment: 1, the inner groove, hole, internal and external threads and other processing equipment: with these characteristics of the shape, we generally want to use a special CNC machine tool – ceramic engraving and milling machine, this machine tool l...Read more -

Performance characteristics and uses of cemented carbide

Cemented carbide is mainly used for cold drawing dies, cold punching dies, cold extrusion dies, cold pier dies and other cold work dies. Carbide cold heading dies are subjected to impact or strong impact wear-resistant working conditions, the commonality of which is the requirement for carbide t...Read more -

Appication of tungsten carbide tips

Carbide tips are widely used in various cutting, drilling and grinding tools, and have the following important functions: 1. High hardness and wear resistance: Carbide tip has extremely high hardness and wear resistance, which can keep cutting and sharpness of drill tip for a long time in the pro...Read more -

Carbide Tooling Heat Treatment Proces

Carbide dies are forged with steel knotted carbide that is softened and annealed prior to cutting. And the steel junction carbide is quenched and tempered after cutting before it is put into use. The common heat treatment processes are spheroidizing annealing, quenching and tempering, which are i...Read more -

The influence of cemented carbide sintering process on product quality

The main production process of cemented carbide products is the sintering process, and sintering has a decisive influence on the performance of cemented carbide products, even if the press billets are the same, using different sintering processes has a different impact on the performance of sinte...Read more -

What are the four stages in the vacuum sintering process of Cemented Carbid

Cemented carbide vacuum sintering is a process in which sintering is performed at a pressure below atmospheric pressure. This process includes plasticizer removal, degassing, solid phase sintering, liquid phase sintering, alloying, densification, and dissolution precipitation. Let’s take a ...Read more