News

-

Carbide grades YG15 and YG20

Due to the difference in hardness and wear resistance, YG15 is generally used in the manufacture of cutting tools, tungsten carbide rollers and other tools that require higher wear resistance, such as cutting tools, impact tools, etc. Due to its ultra-high hardness, YG20 is generally used to make...Read more -

Application of cemented carbide hot forging dies

Carbide hot forging dies are often used to produce metal parts, especially parts that require shape processing at high temperatures and pressures. Tungsten carbide hot forging dies are usually used in the forging process. After the metal is heated to a certain temperature, pressure is applied to...Read more -

Application and classification of carbide screw dies

Carbide screw dies are commonly used to produce various types of screws, including machine screws, automotive screws, aviation screws, electronic equipment screws, etc. These screws usually require high precision, high quality and high strength, so carbide screw dies can meet these requirements a...Read more -

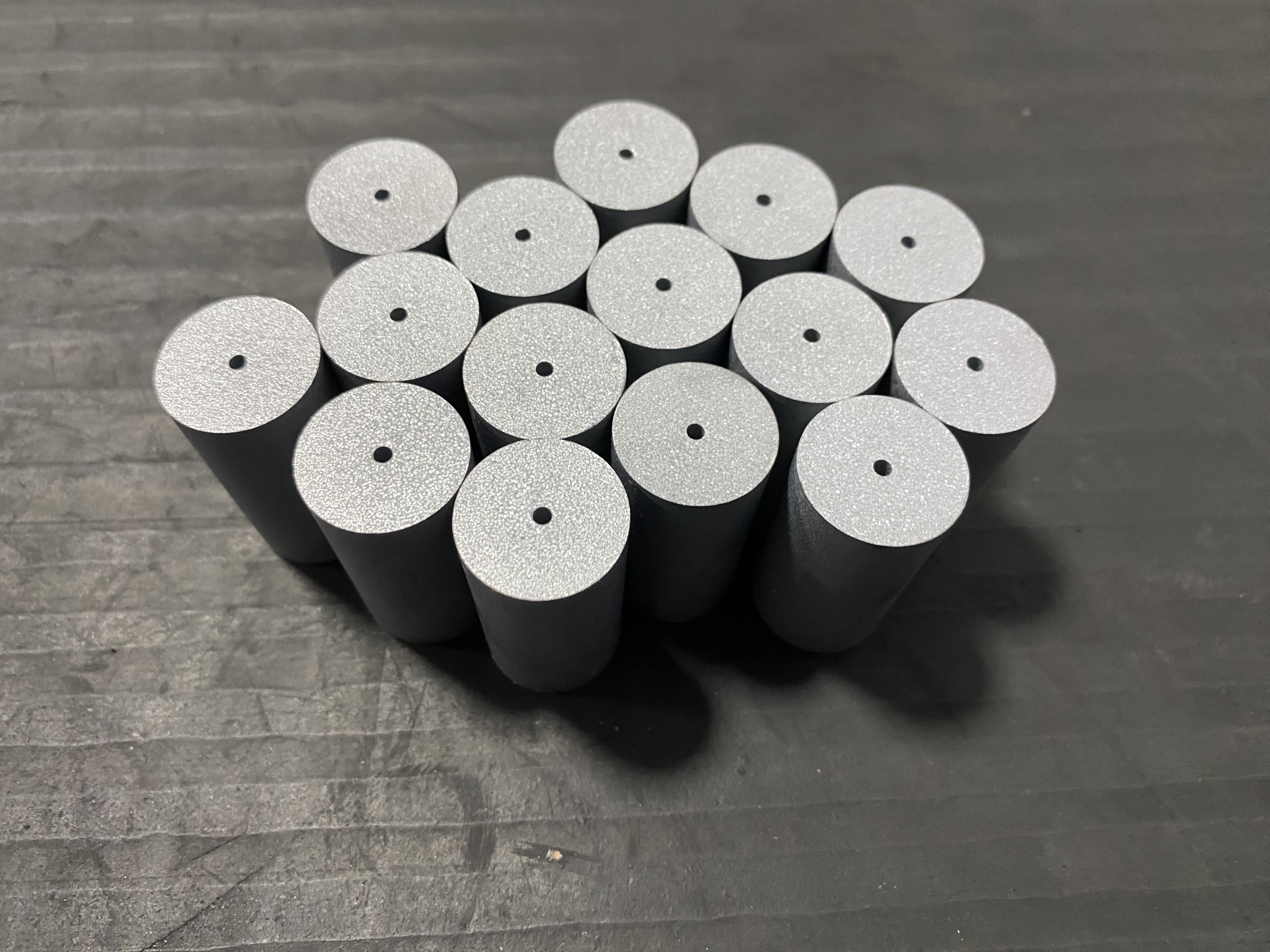

Technical requirements for carbide screw molds

A carbide screw mold is a mold used to make screws, usually made of carbide. This mold can be used to manufacture screws of various specifications and models in industrial production. This type of screw die is commonly used in metal processing and machine manufacturing. Carbide screw molds usuall...Read more -

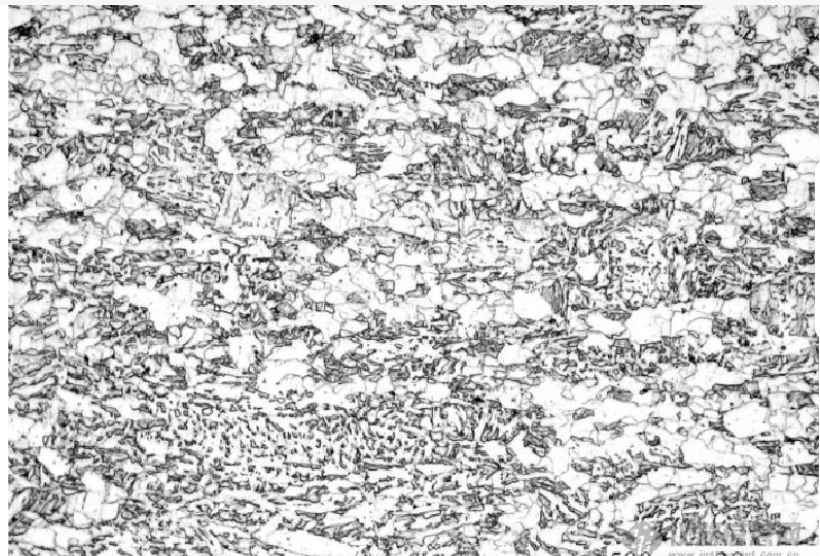

Hard alloy crystal granularity

The granularity control of the hard alloy production process is undoubtedly one of the key to the quality control of the hard alloy, but it is quite difficult for the average size and the quantitative determination and description of the grain distribution of the hard phase grain size in the hard...Read more -

The effect of pore degree on quality

Tungsten carbide pores are generally caused by impurities in the blank block before sintering. Due to the uneven distribution of the pores in the sample, a few more fields should be observed. When detecting, you can observe one by one (from the edge of the sample section to the center). Select th...Read more -

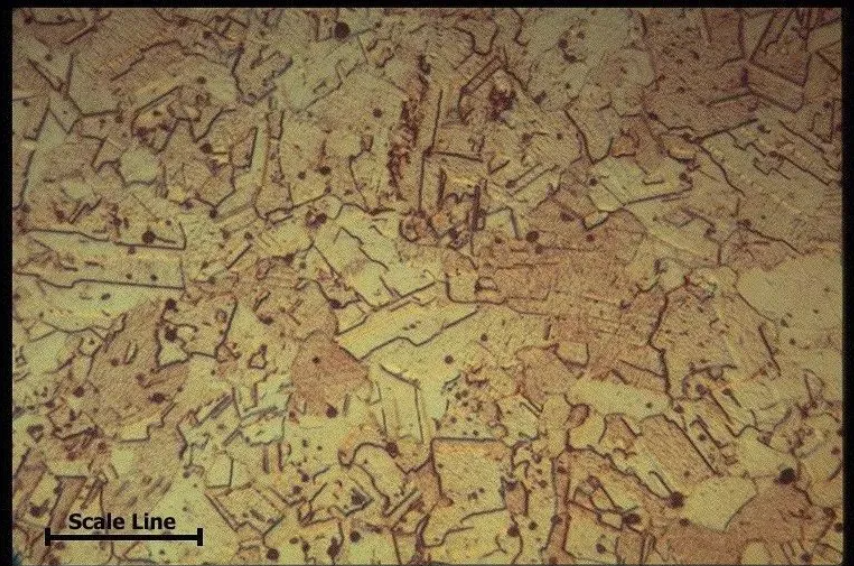

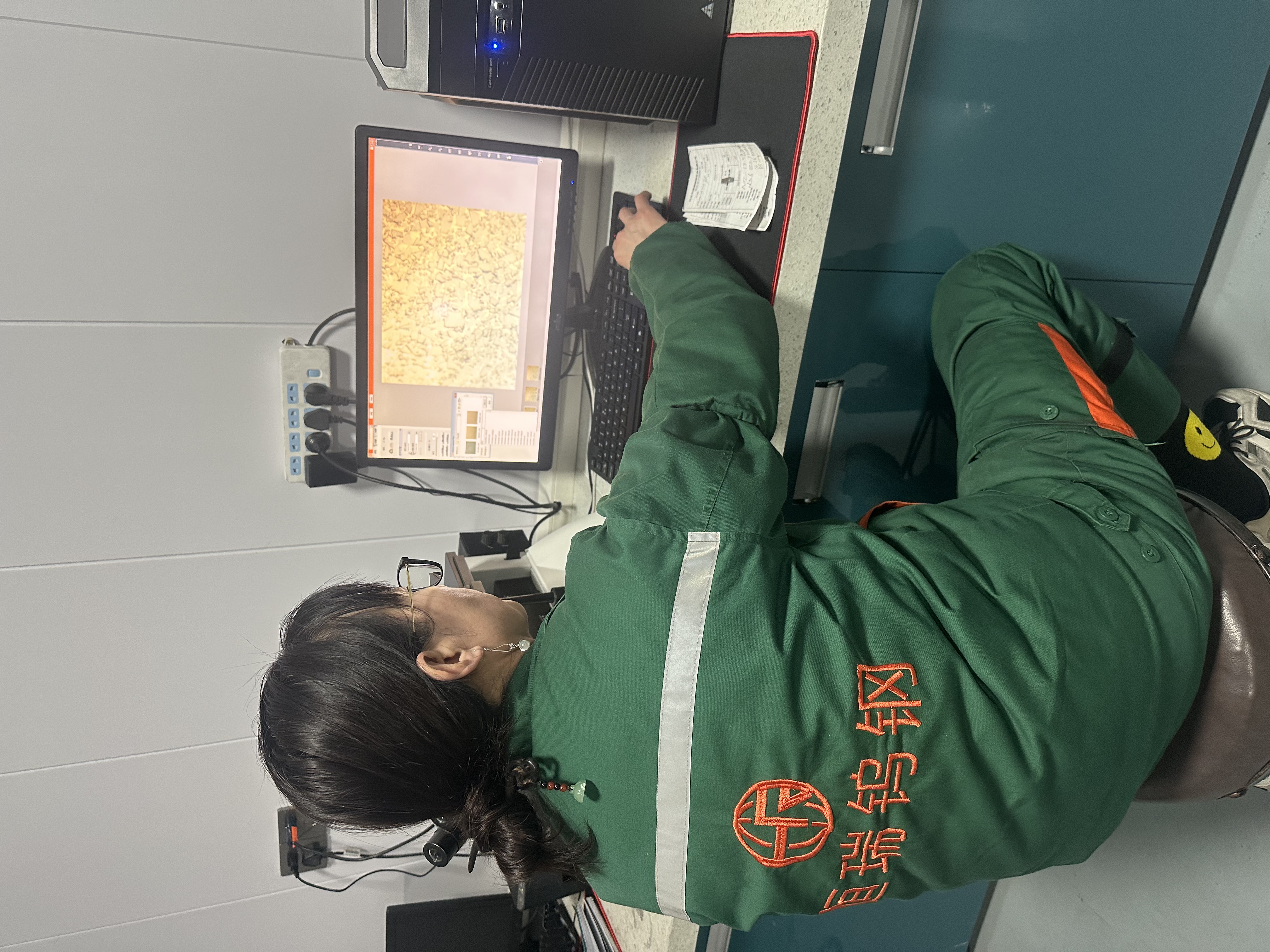

Tungsten carbide gold phase detection

Gold phase test is a method of evaluating its performance and quality through micro -organizations that observe metal materials. For tungsten carbide alloy production, the gold phase test has important guiding significance. The gold phase test can observe the microcontrollers of the alloy through...Read more -

The coercive force of cemented carbide is a structural parameter related to technical magnetization.

It is related to the content of cobalt in the binder phase in the alloy, as well as the grain shape and dispersion (cobalt layer thickness) of cobalt, as well as the lattice distortion, internal stress and the presence of impurities of cobalt. Generally speaking, the coercive force of cemented ca...Read more -

Determination of cemented carbide density

Density is one of the most basic physical properties of materials. Density is the mass per unit volume of a material, represented by the symbol p, and its unit is g/cm. When the grade of cemented carbide is known, by measuring its density, we can examine whether the composition and structure of ...Read more -

Tungsten carbide grain size classification

This type of alloy is called YG type alloy. The normal structure of WC-Co alloy white is a two-phase alloy composed of polygonal WC phase and bonding phase Co. Sometimes less than 2% of other (tantalum, niobium, chromium, vanadium) carbides are added as additives to the cutting blade or drawing d...Read more -

The function of cemented carbide forming agent

(1) Bond the fine powder particles into slightly coarser particles to improve the fluidity of the powder and improve the compact density distribution uniformity. (2) Give the briquette the necessary strength. Carbide materials produce almost no plastic deformation, and the strength of the compac...Read more -

Carbide precision automatic molding equipment

There are three types of equipment used for precision pressing in cemented carbide production: mechanical, hydraulic and electric. Mechanical presses are rigid pressing and have high positioning accuracy. They have always been the preferred equipment for precision pressing of tungsten carbide. Du...Read more