Is tungsten carbide stronger than diamond?Debunking Myths

When it comes to the world of materials and their properties, the debate over which substance dominates in terms of strength has long been a fascinating topic. One of the most common comparisons is between tungsten carbide and diamond. Both are known for their exceptional stiffness and durability, but which one really stands out? In this blog, we’ll delve into the properties of tungsten carbide and diamond, debunking myths and revealing the truth behind their strength.

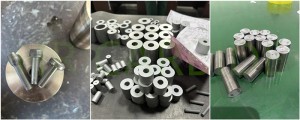

Tungsten carbide cold heading dies is a compound made of tungsten and carbon atoms and is known for its exceptional hardness and wear resistance. It is frequently used in industrial applications such as cutting tools, drill bits, and armor-piercing ammunition. Diamond, on the other hand, is a naturally occurring mineral composed of carbon atoms arranged in a lattice structure, making it the hardest known material in the world. Tungsten carbide and diamond are both valued for their hardness, but the key is to understand the different properties that determine their strength.

While GT55 tungsten carbide pellets is extremely hard and durable, it is still not as hard as diamond, which is unparalleled. Diamonds top the Mohs scale of mineral hardness, scoring out of 10, while tungsten carbide typically falls between 8.5 and 9.0 on the same hardness scale. This means that diamond is inherently stronger and more resistant to scratches and wear than tungsten carbide. However, it is important to note that hardness is only one aspect of strength and other factors come into play when evaluating the overall performance of these materials.

In terms of toughness, tungsten carbide rollers exhibits superior strength than diamond. Toughness refers to a material’s ability to withstand impact and resist cracking or chipping. Although diamond is very hard, it is also brittle and easily breaks under certain conditions. Tungsten carbide, on the other hand, is known for its exceptional toughness, allowing it to withstand high stress environments without cracking. This makes tungsten carbide the first choice for applications that require resilience and durability under severe wear and tear.

Another key factor to consider is the application-specific properties of tungsten carbide dies and diamond. Diamond has excellent hardness and is commonly used in cutting, grinding, and polishing tools, while tungsten carbide is favored for its toughness and wear resistance in applications such as mining, drilling, and metalworking. The choice between these materials ultimately depends on the specific requirements of the intended use, as each material offers unique advantages based on its inherent properties.

In summary, the debate over whether tungsten carbide cold rolls is stronger than diamond ultimately comes down to understanding the unique properties and strength of each material. While diamond dominates in terms of hardness, tungsten carbide holds its own in terms of toughness and elasticity. Both materials have their own advantages and limitations, making them suitable for different applications based on the specific requirements of the task at hand. Rather than pitting these materials against each other, it is important to recognize and appreciate the unique qualities that make tungsten zhuzhou carbide and diamond each useful in the field of materials science.

https://www.ihrcarbide.com/

Post time: May-14-2024