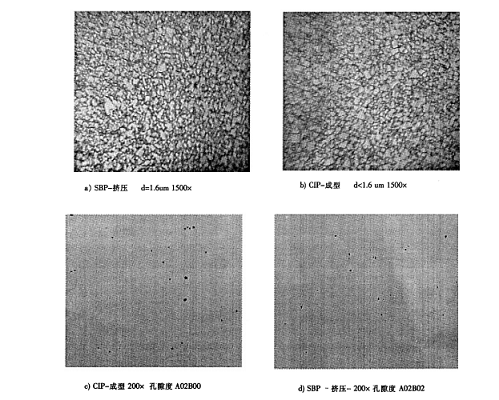

YG6 tungsten carbide was used as experimental raw material, and plasticizer mainly composed of SBP was added (SBP addition amount 120ml/kg~180mlkg), and extrusion feed was prepared by full mixing. Extruded blank samples were obtained on a special extruder. After degreasing-conventional vacuum sintering, the product density distribution, bending strength, conventional metallographic, etc. were tested, and the relevant properties of YG6 tungsten carbide samples obtained by CIP molding were compared.

The amount of plasticizer added has an important influence on the extrusion process (Figure 1). With the increase of SBP content, the density of the extruded blank decreases, which has an adverse effect on improving the strength of the blank and is easy to cause deformation of the blank. Moreover, with the increase of plasticizer content, the required extrusion pressure also decreases. Experiments show that the correct selection of plasticizer content is the primary factor for successful extrusion, because plasticizer mainly plays a bonding role, which directly affects the bonding force between powder particles.

When the SBP content is too high, in addition to completely covering the powder particles, the plasticizer also accumulates on the surface of the powder body, which reduces the extrusion pressure and weakens the bonding force between the powder particles, thereby reducing the strength of the tungsten carbide blank, making the extruded parts easy to break and difficult to form; on the contrary, when the plasticizer content is too low, the plasticizer cannot completely cover the surface of the powder particles. During extrusion, due to the relative movement between the powder particles, a large friction resistance is generated, thereby increasing the extrusion pressure, causing the internal stress of the blank to increase, and finally causing transverse cracks or delamination fractures in the blank, resulting in extrusion failure.

Post time: Aug-08-2024