india popular size tungsten carbide cold heading mould from in stock

All of our heading dies are sintered by HIP furnace, and we used the excellent raw material, our heading dies was exported to Germany, Italy, Turkey, South east Asia and Japan, the qty of our heading die production is over 20 MT per month, and the quality if very competive.

Our factory is equipped with state-of-the-art machinery and technology, allowing us to produce precision-engineered carbide molds with utmost accuracy and efficiency. We invest in the latest equipment to ensure that our products meet the highest standards and exceed customer expectations.

Quality is at the forefront of everything we do. We adhere to strict quality control measures throughout the production process to ensure that every carbide mold that leaves our factory meets the highest quality standards.

We understand that every project is unique, and we offer customization options to meet your specific requirements. Whether you need a standard carbide mold or a custom-designed solution, we have the capabilities to fulfill your needs.

Cemented Carbide Cold Heading Mold is compatible with a range of cold heading machines, offering versatility and ease of integration into existing manufacturing processes. Whether used for mass production or custom manufacturing, this mold delivers reliable and consistent results, making it a valuable asset for fastener manufacturers.

We can send international express such as DHL, FedEx, UPS, SF Express, etc. We can also choose lower-cost shipping methods such as sea transportation and air transportation.

1. What is tungsten carbide and why is it used in mold manufacturing?

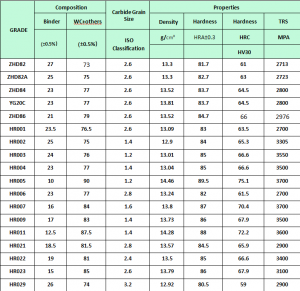

Tungsten carbide is a composite material made of tungsten and carbon. It is widely used in mold manufacturing due to its exceptional hardness, wear resistance, and high temperature tolerance, making it ideal for producing high-quality and durable molds.

2. How can a tungsten carbide mold solve usage problems?

Tungsten carbide molds are known for their precision and durability, which allows them to effectively address common usage problems such as wear and tear, deformation, and poor mold quality. Their superior performance ensures consistent and reliable mold usage.

3. Can tungsten carbide molds be customized to specific requirements?

Yes, as an experienced tungsten carbide mold manufacturer, we have the capability to customize molds according to specific requirements. Whether it's a unique design, size, or material composition, we can tailor the molds to meet the exact needs of our customers.

4. What sets your company apart in terms of tungsten carbide mold production?

With 18 years of production experience, our company has developed a deep understanding of tungsten carbide mold manufacturing. We combine our expertise with advanced technology to deliver high-quality molds that excel in performance and longevity, setting us apart from other manufacturers.

5. What industries can benefit from using tungsten carbide molds?

Various industries, including automotive, aerospace, electronics, and manufacturing, can benefit from using tungsten carbide molds. These molds are suitable for producing a wide range of components and products that require precision, durability, and resistance to harsh operating conditions.