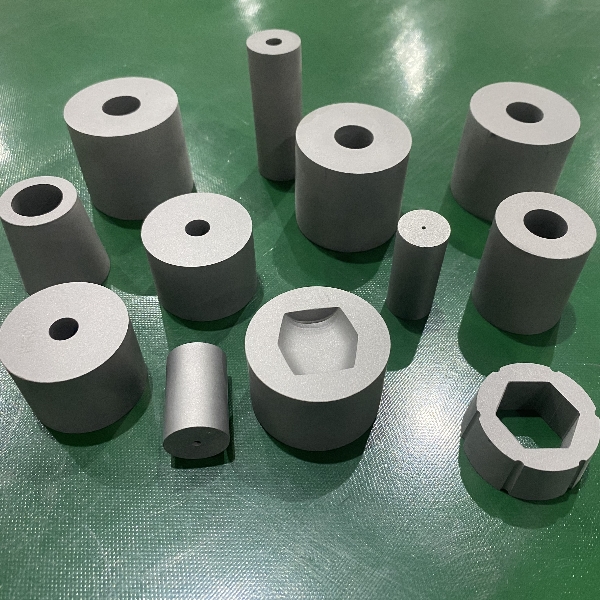

BOLT AND NUT FORMING DIES Tungsten Carbide Dies Tungsten Carbide Manufacturers

Our tungsten carbide screw pallets are engineered to provide a safe and stable platform for securing and transporting screws, bolts and other small parts during production. The pallet's precision-engineered dimensions and smooth surface ensure seamless handling and transfer of parts, helping to increase operational efficiency and productivity.

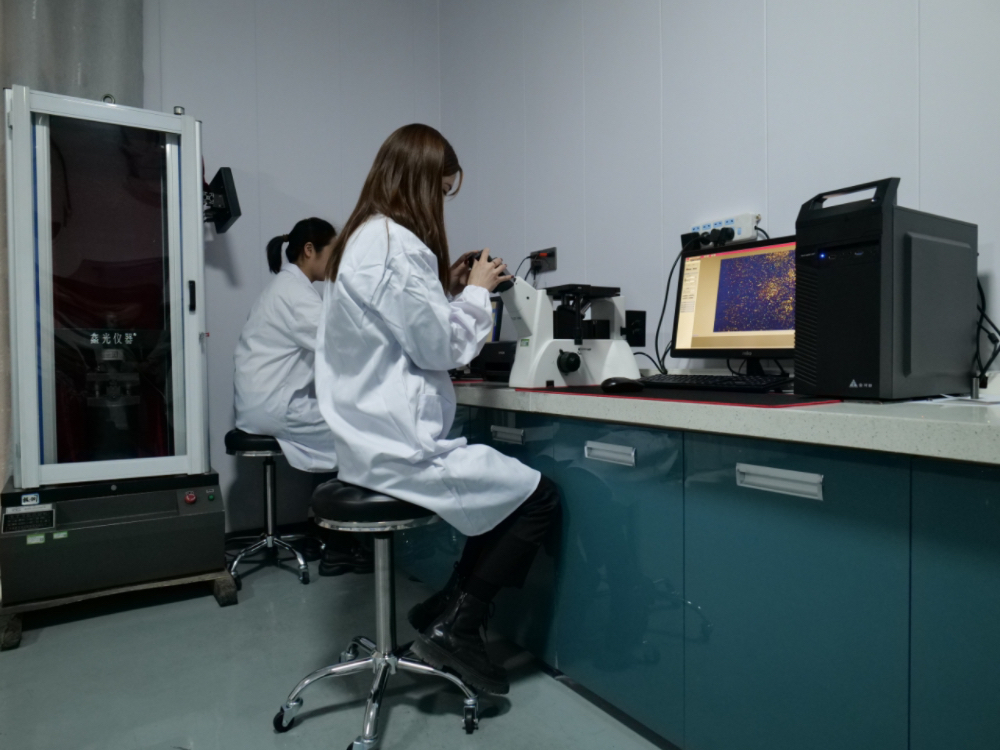

We focus on quality and performance and our screw pallets undergo rigorous testing and quality control measures to ensure they meet the highest standards of excellence. We are committed to delivering products that exceed customer expectations and provide lasting value.

In addition to their exceptional durability and reliability, our tungsten carbide screw trays can be easily integrated into existing manufacturing systems, making them compatible with a variety of equipment and processes. This versatility makes them a valuable asset in various industries including automotive, aerospace, electronics, and more.

Whether you need reliable parts handling, assembly or storage solutions, our tungsten carbide screw trays are engineered to deliver outstanding performance and longevity, making them an indispensable tool for optimizing manufacturing operations.

Experience the difference our tungsten carbide screw mold trays can make in your production process. Contact us today to learn more about how our high-quality pallets can improve the efficiency and reliability of your operations.

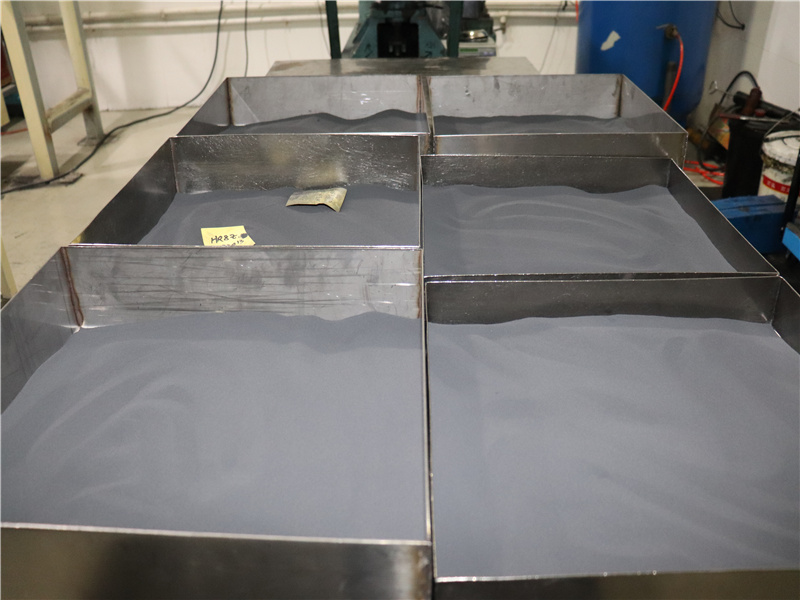

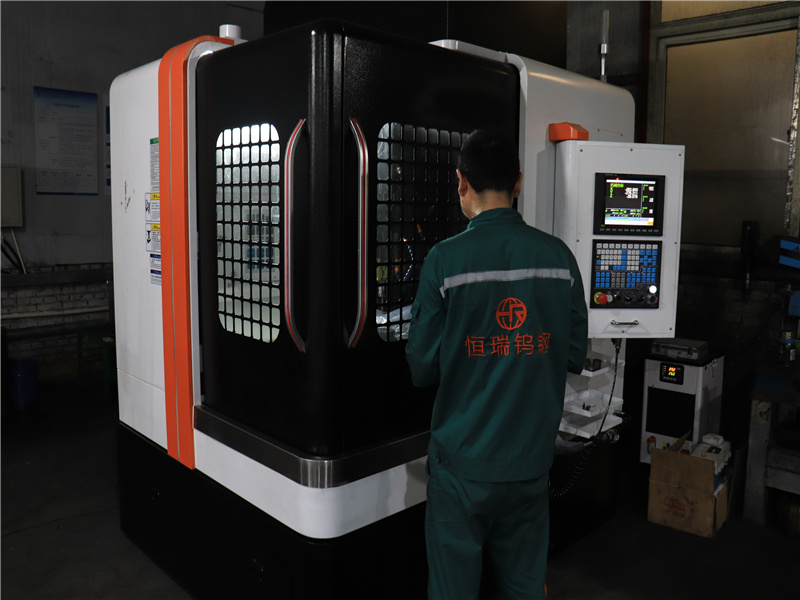

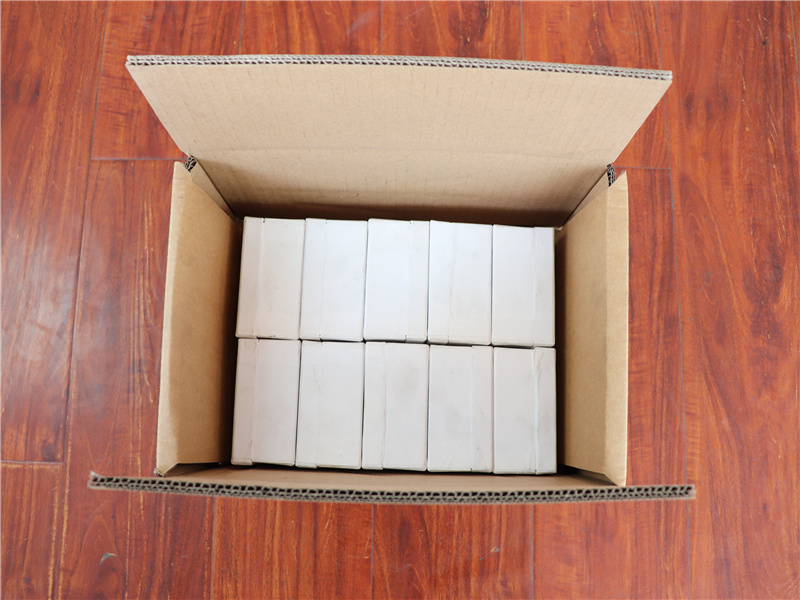

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

Shipping express

We have opened dedicated logistics lines for ten countries including Vietnam, Russia, India, Indonesia, Pakistan and Malaysia.

Are the hexagonal heads of the screws protruded?

A: Most of them are made of piers, because this can save materials. Depending on the tonnage of the pier forging machine and the bolt diameter, cold pier or hot pier technology can be used.

02

Are the bolts entirely die cast?

A:If the bolt material is an alloy or metal with a low melting point such as aluminum alloy, zinc alloy, copper alloy, etc., die casting can also be used. Steel ones are not made by die casting.

03

What's your delivery time for our orders?

A: The delivery is about 3day for standard productsand 25-30 days for OEM products.