HR carbide Cold Hot Forging Tungsten Carbide Dies Straight Hole Die

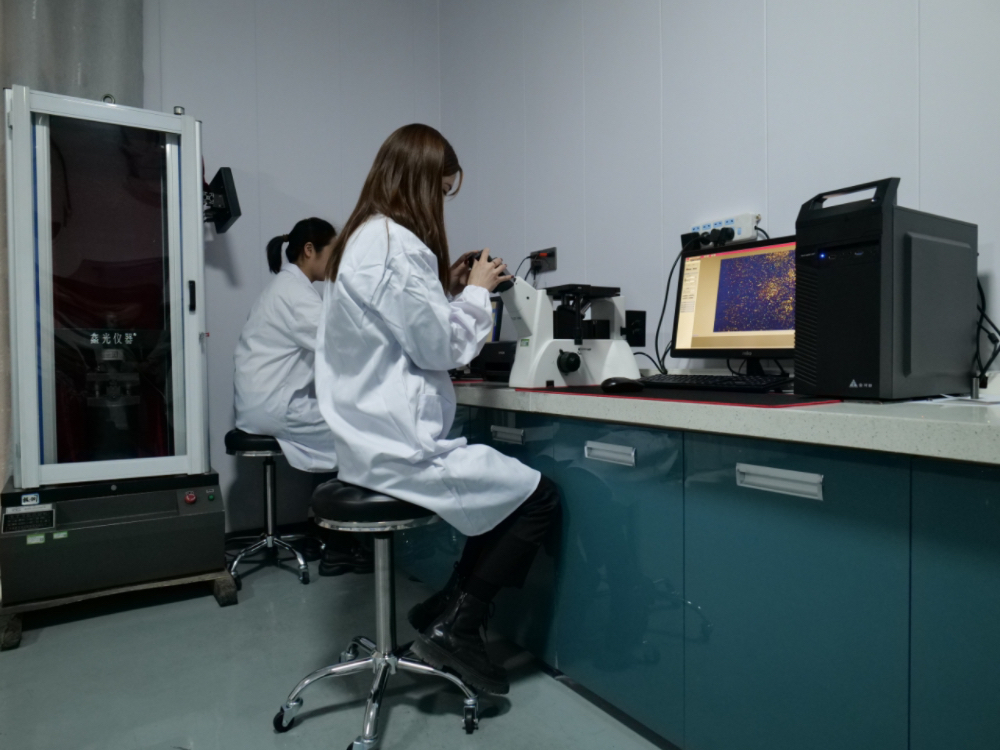

Since its establishment, Renqiu Hengrui Cemented Carbide Co., Ltd. has attached great importance to the talent development strategy. It has a production and R&D team of senior engineers, engineers, and technical backbones, and has established industry-university-research demonstration cooperation with the metal materials disciplines of universities and colleges to be able to Provide comprehensive product design, technical solutions, technical training and technical consultation for all types of users, and assist users in solving various problems encountered during the use of tungsten carbide molds.

The company insists on using high-end talents and high-end technical equipment to create high-end, high-quality cemented carbide products, establish China's national cemented carbide brand, and make Zhuzhou manufacturing famous in the world.

The company adheres to innovative development, uses new process technology, and efficiently develops new products, and meets the needs of global customers with strong supply capabilities, fast delivery, and stable product quality.

(1) the blanking die separates the material along the closed or open contour line. Such as blanking die, punching die, cutting die, cutting die, cutting die, cutting die and so on.

(2) the bending die makes the blank or other blank produce bending deformation along the straight line (bending curve), so as to obtain a certain angle and shape of the workpiece mold.

(3) the drawing die is a die which can make blank into open hollow part or make hollow part change shape and size further.

(4) the forming die is a kind of die which can directly copy the blank or semi-finished workpiece according to the shape of the convex and concave die, while the material itself only produces local plastic deformation. Such as bulging die, necking die, expanding die, rolling forming die, flanging die, shaping die, etc.

Tungsten carbide cold heading mold is a common mold in industrial manufacturing. It is mainly used to produce various metal parts, especially small-diameter screws, nuts and studs. In order to meet the needs of high-speed production, cold emblem molds need to have the characteristics of high hardness, high strength, high wear resistance and high crack resistance. Carbide material is a very ideal material, which can meet the requirements of cold heading molds.

Cold heading molds can be designed and produced according to the size of the product

We can send international express such as DHL, FedEx, UPS, SF Express, etc. We can also choose lower-cost shipping methods such as sea transportation and air transportation.

1. What is tungsten carbide and why is it used in mold manufacturing?

Tungsten carbide is a composite material made of tungsten and carbon. It is widely used in mold manufacturing due to its exceptional hardness, wear resistance, and high temperature tolerance, making it ideal for producing high-quality and durable molds.

2. How can a tungsten carbide mold solve usage problems?

Tungsten carbide molds are known for their precision and durability, which allows them to effectively address common usage problems such as wear and tear, deformation, and poor mold quality. Their superior performance ensures consistent and reliable mold usage.

3. Can tungsten carbide molds be customized to specific requirements?

Yes, as an experienced tungsten carbide mold manufacturer, we have the capability to customize molds according to specific requirements. Whether it's a unique design, size, or material composition, we can tailor the molds to meet the exact needs of our customers.

4. What sets your company apart in terms of tungsten carbide mold production?

With 18 years of production experience, our company has developed a deep understanding of tungsten carbide mold manufacturing. We combine our expertise with advanced technology to deliver high-quality molds that excel in performance and longevity, setting us apart from other manufacturers.

5. What industries can benefit from using tungsten carbide molds?

Various industries, including automotive, aerospace, electronics, and manufacturing, can benefit from using tungsten carbide molds. These molds are suitable for producing a wide range of components and products that require precision, durability, and resistance to harsh operating conditions.