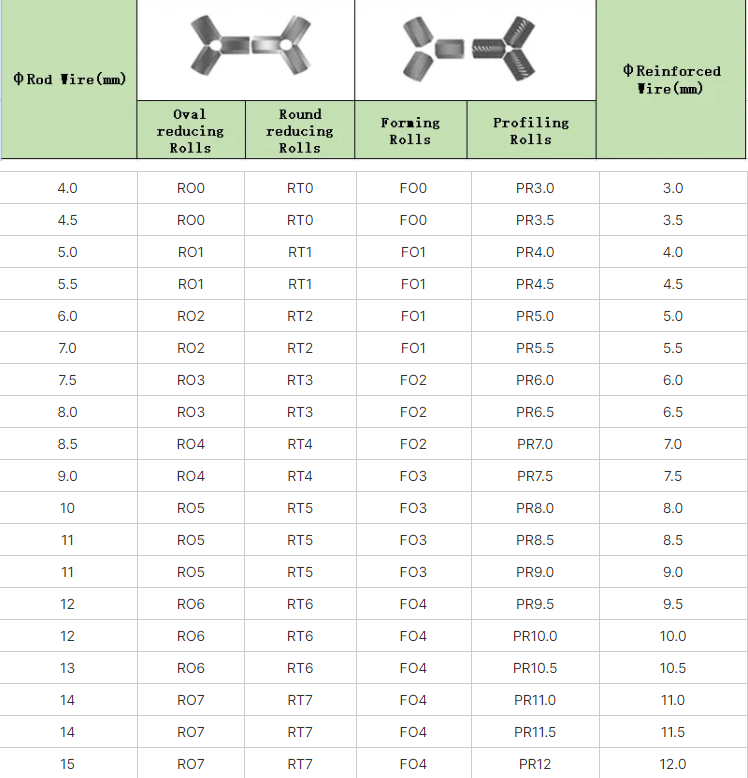

Hot sale tungsten carbide straightening rollers RO roller RT roller for wire mills

Specializing in the production of various cemented carbide rollers

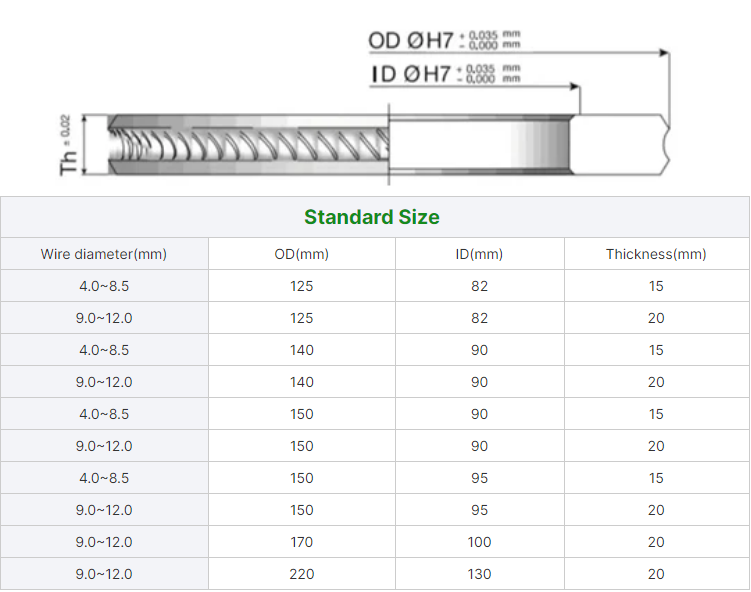

Specializing in the production of carbide rolls for cold-rolled ribbed steel bars, three-sided rib rolls, two-sided rib pairs, arcs, and centering wheels. We design single-groove, double-groove, three-groove, and four-groove alloy roll pairs according to user requirements. Produces carbide rollers of various specifications ranging from $4 to ∮12.

Good products win the favor of customers from all over the world

Produced in accordance with GB13788--2008, using good alloy materials and manufacturing processes, the rolled products have high smoothness and moderate prices, winning the favor of users from all over the world and bringing greater economic benefits to users.

Win the market with integrity and conquer the world with quality

"To conquer the market with integrity and conquer the world with quality" is our company's business philosophy and foundation. We will provide you with high-quality services with excellent quality, preferential prices, diverse varieties and short delivery times.

Provide fast and in-depth after-sales service to give you peace of mind

We have a variety of raw materials and production equipment to ensure the timely supply of partner products. We are online 24 hours a day and are ready to solve any problems you encounter during use!