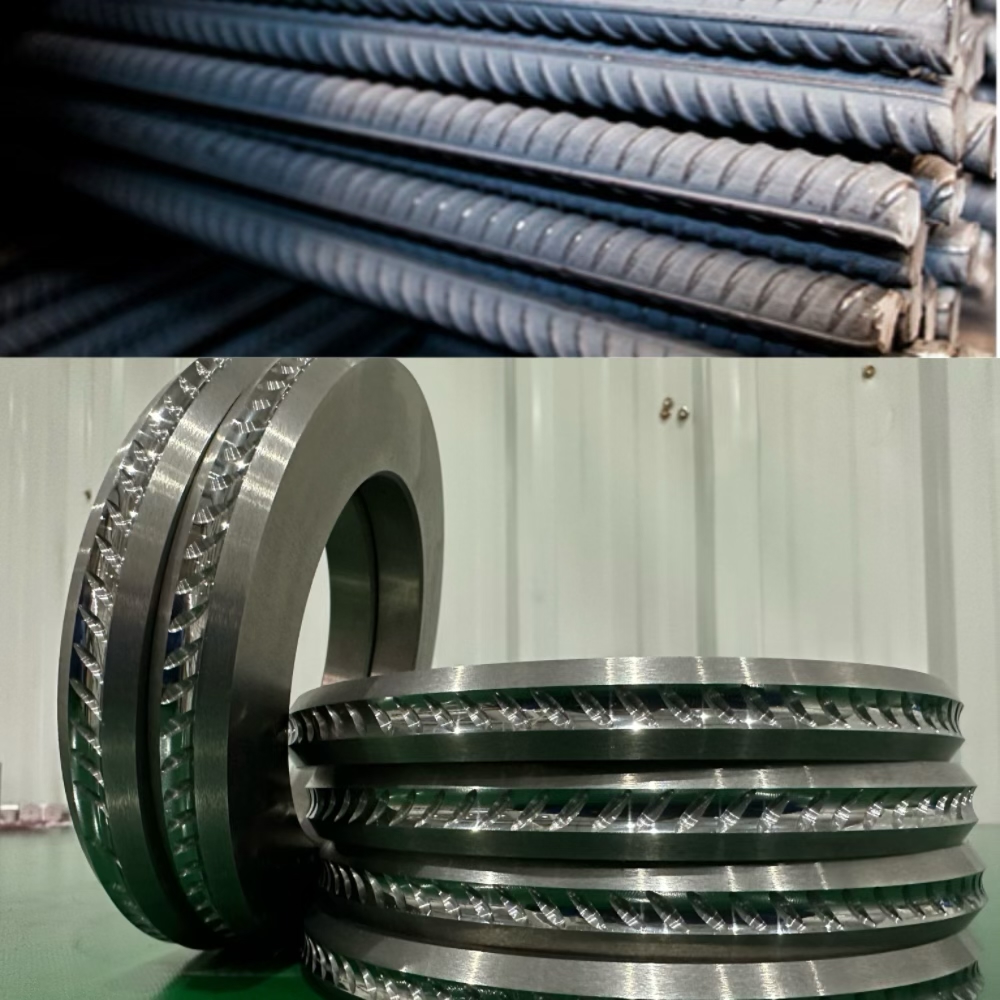

Hot sale tungsten carbide straightening rollers for wire mills with high hardness

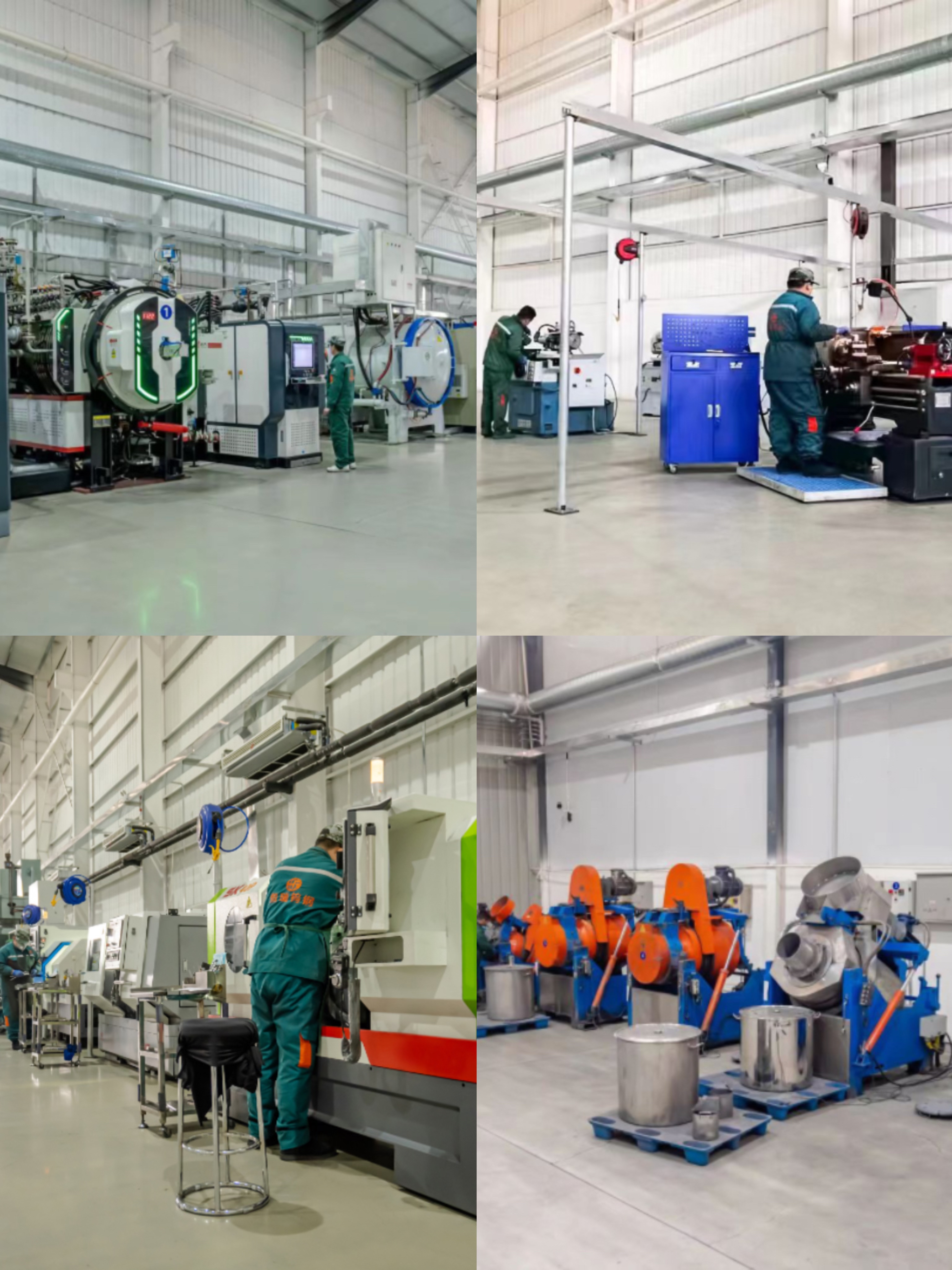

HRNGRUI tungsten carbide rollers are produced by isostatic suppressing and HIP sintering,which are the most advanced facilities to ensure the stable properties,which reduces the production cost and improves the rebars quality with high precision on dimension,clear ribs and beautiful surface.

Weigh the required raw materials of each component and a small amount of additives, and put them into a rolling ball machine or a stirring ball machine. Under the impact and grinding action of the alloy ball grinding body in the ball mill, the raw materials of each component are refined in the hexane grinding medium. And evenly distributed, add a certain amount of liquid paraffin before spray drying (or in the later stage of wet grinding), and after unloading, spray dry, vibrate and sieve (or vacuum dry, homogenize, crush and sieve) to make a certain composition and particle size Required wax blends to meet press molding and vacuum sintering needs

Contact Us