High quality Tungsten Carbide Roller Rolls holders used for the cold rolling process

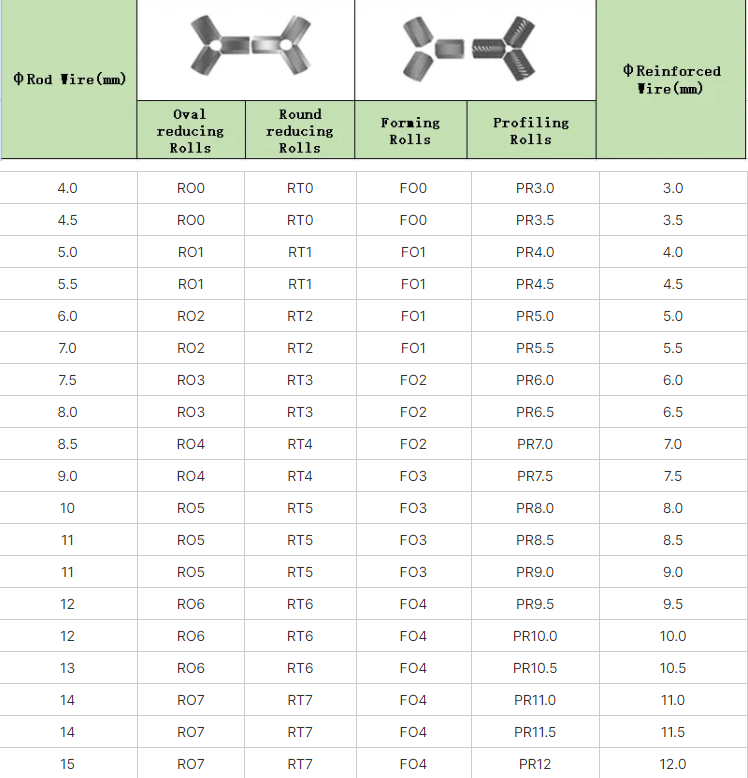

Service is to be available for the design, groove machining and rid machining of composite cemented carbide roll. Various matching tools can be provided for machining composite e cemented carbide roll.

Bonding-type and thermal interference-type composite rolls can be provided according to customers’requests. Special cemented carbide grades for rolling ribbed steel bars and rods can be developed according to customers' requests.

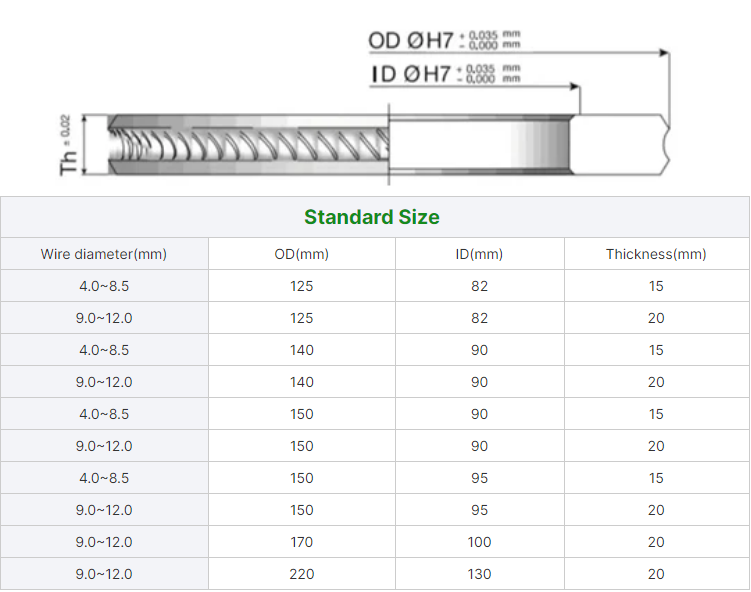

Various cemented carbide roll rings are available with diamete er of 300~400mm and thickness of 30~150mm for rod reducing and sizing machines.

1. What are the advantages of your products?

From raw material production to processing, grinding and polishing rollers, engineers with more than decades of work experience are responsible for the production, which can ensure product quality and provide the lowest factory price.

2. Can you provide door-to-door service?

Not yet, we do not have distributors abroad, but we can provide 24-hour online free consultation.

3. Can you help with product selection and grade selection?

Of course, we have 58 different grades of tungsten carbide, and we can also customize grades to supply different prices, different countries, and different markets.