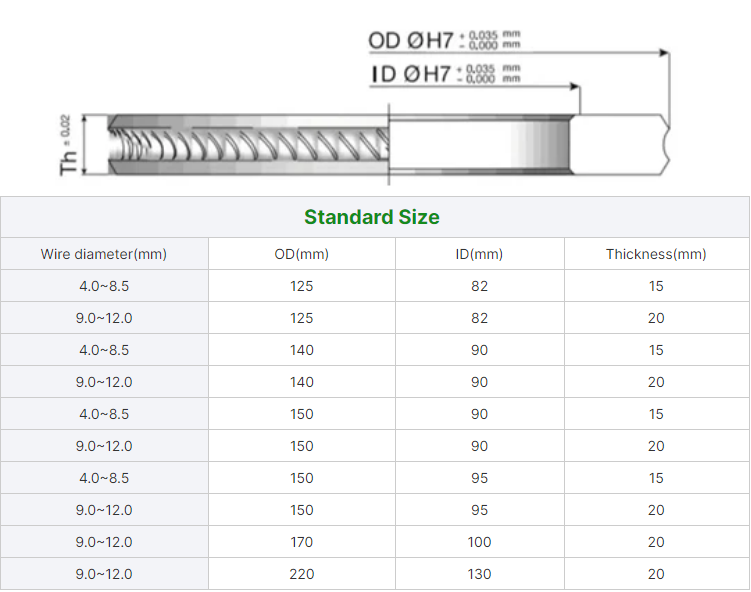

High Precision Tungsten Carbide Roller Holder for 150X90X15mm Carbide Roller

Process

powder milling → formula according to grade→ wet grinding → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain a mixture → granulating → pressing → forming → Sintering →preforms→rough machining by flat grinding→non-destructive ultrasonic flaw detection →finishing machining by flat grinding→internal grinding →external grinding→chamfering→notching machining→laser marking→inspection →packing → Storage

1. What are the advantages of your products?

From raw material production to processing, grinding and polishing rollers, engineers with more than decades of work experience are responsible for the production, which can ensure product quality and provide the lowest factory price.

2. Can you provide door-to-door service?

Not yet, we do not have distributors abroad, but we can provide 24-hour online free consultation.

3. Can you help with product selection and grade selection?

Of course, we have 58 different grades of tungsten carbide, and we can also customize grades to supply different prices, different countries, and different markets.