The company adheres to honesty and win-win cooperation. In the development of the company, it not only needs to serve customers well and safeguard customer interests, but also pays attention to the cooperative development of suppliers. Now it has established a complete and close supply system, which has laid a solid and solid foundation for the company's business expansion. Base.

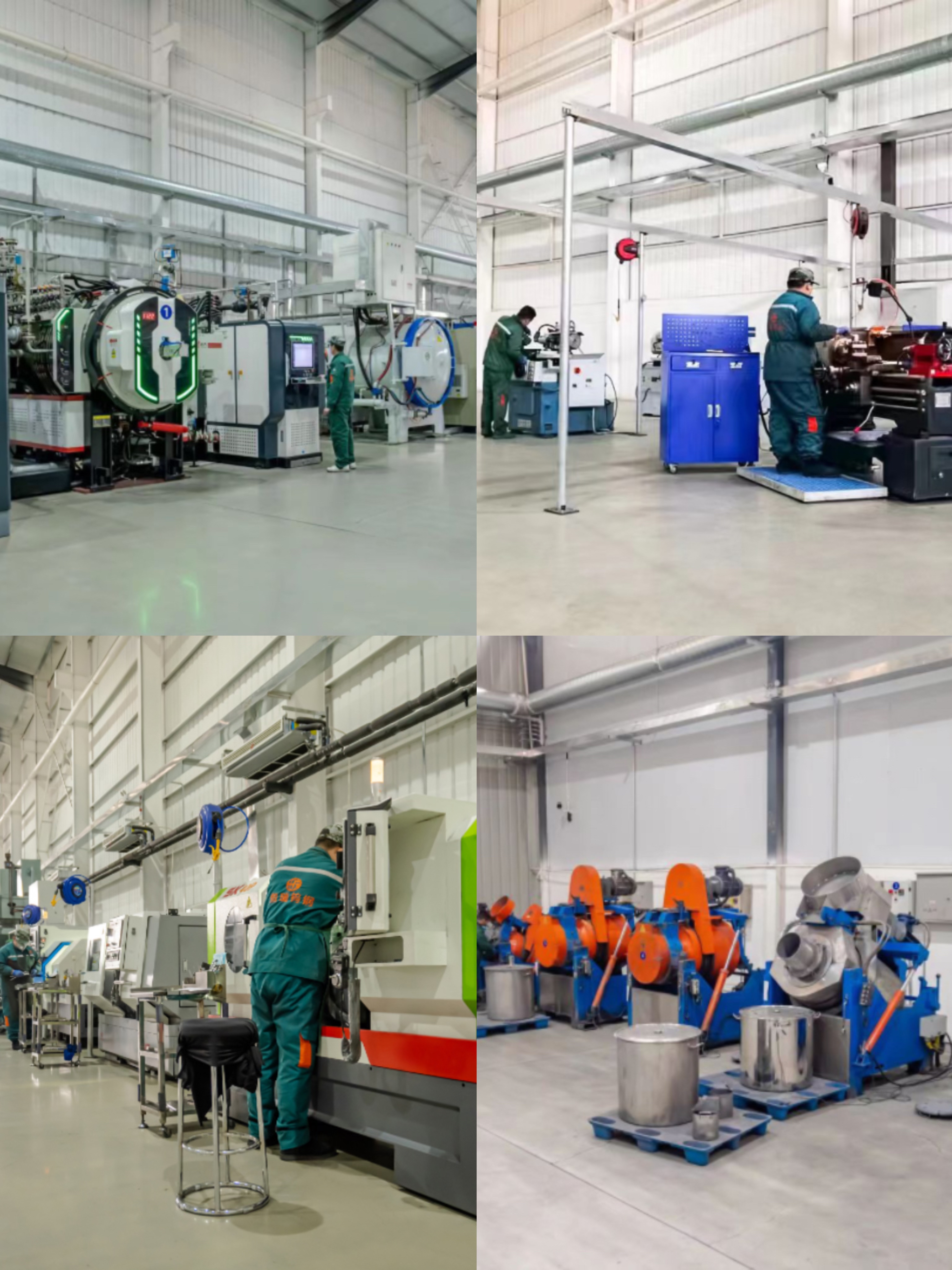

The company adheres to innovation and development, develops new products with new processes and technologies, and efficiently develops new products, especially in the fields of non-standard, special-shaped and carbide materials, and satisfies global customers with strong supply capacity, fast delivery guarantee, and stable product quality. need.

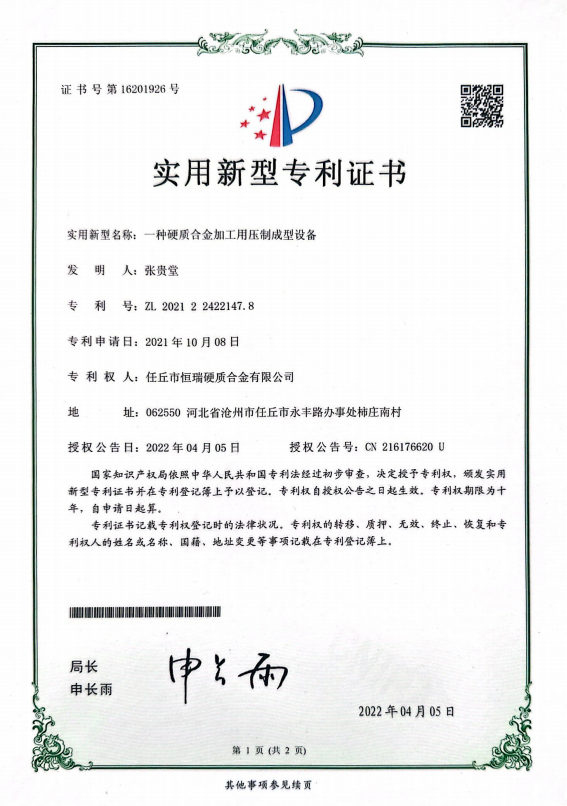

We have passed and strictly implemented the ISO9001:2015 quality management system, have independent import and export rights, obtained multiple product invention patents, and won the Alibaba Special Contribution Award, high-tech enterprise and other honors

High Precision Tungsten Carbide Cold Forming/Profiling Roller Tool Holder

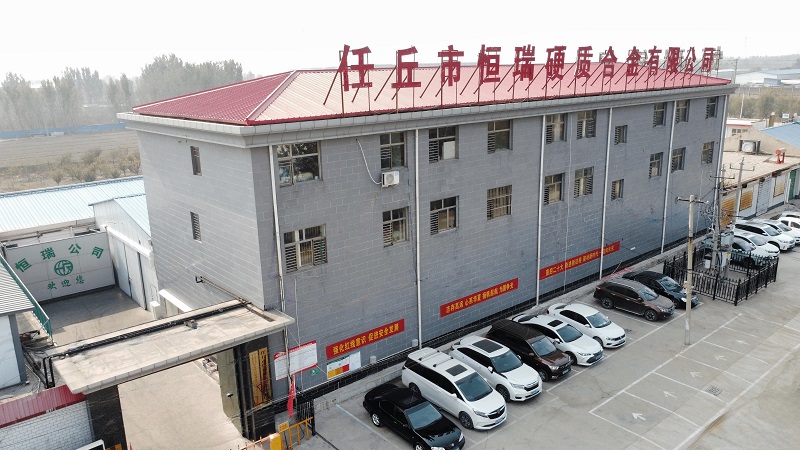

Renqiu Hengrui Cemented Carbide was established in 2006. The company's strategic goal is to build a large-scale cemented carbide group enterprise. Renqiu Hengrui Cemented Carbide Co., Ltd. is a one-stop cemented carbide production and customization service provider. Through years of development, Jinxin Company has won the favor of customers with its stable product quality and rich product categories. The company has established a foreign trade department in 2020, and its products are sold at home and abroad.

Since its establishment, Renqiu Hengrui Cemented Carbide Group Co., Ltd. has attached great importance to the talent development strategy, hired a professional production and R&D team, and established industry-university-research demonstration cooperation with the metal materials disciplines of colleges and universities, so as to provide comprehensive services to all types of users. Product design, technical solutions, technical training and technical consultation, etc., help users solve various problems encountered during use.

Powdering → Formula according to application requirements → Wet grinding → Mixing → Crushing → Drying → Sieving → Then add molding agent → Dry again → Sieve to prepare the mixture → Granulation → Cold isostatic pressing → Molding → Sintering → Forming (blank) → packaging → warehousing.

Contact Us