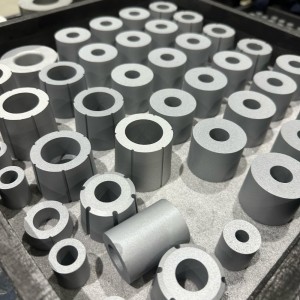

GT55 Tungsten Carbide Pellets For Cold Heading Dies With Good Od Grinding

1. 19 year's manufacturing experience.

2. 100% virgin raw material guaranted the long life time

3. Fast delivery time

4. Superior quality

1.Cemented carbide pellets are widely used in cold heading dies and punching dies

for manufacturing nuts, bolts and many other products.

2.The grade GT55/YG25C is the most widely used material in making carbide pellets.

It has excellent properties which lead to good performance and long service time.

3.Except for the standard sizes, nonstandard sizes of carbide pellets

can also be produced according to customer's requirements.

4.All carbide pellets inspected strictly with ultrasonic flaw detector

to avoid ones with blowholes or cracks leaving the factory.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Our cold heading dies are engineered with unwavering attention to detail. Each die is meticulously designed to ensure flawless shaping and forming of metal rods, delivering products that adhere to the strictest tolerances and specifications.

1. Use 100% tungsten carbide raw material.

2. Stable chemical properties

3. Excellent performance and good wear/corrosion resistance

4. HIP sintering,good compactness

5. Blanks,high machining accuracy/precision

6. OEM customized sizes available

7. Factory’s offer

8. Strict products quality inspection

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 7days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% T/T before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.