Good Wholesale Vendors Tungsten Carbide Brazing Rod - Tungsten Carbide Guide Roller – HengRui

Good Wholesale Vendors Tungsten Carbide Brazing Rod - Tungsten Carbide Guide Roller – HengRui Detail:

Why Choose Us

1. Chinese factory specialized in processing and production, ISO certification.

2. Multiple sizes and types available for OEM.

3. Made of 100% original high-quality materials

4. Professional production team, fast delivery

5. Free professional after-sales service and technical support

products description

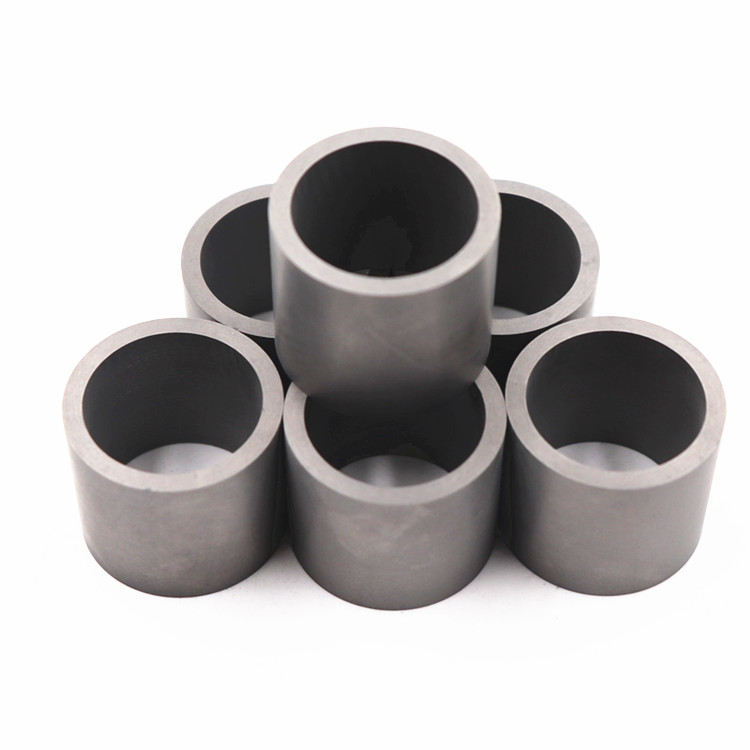

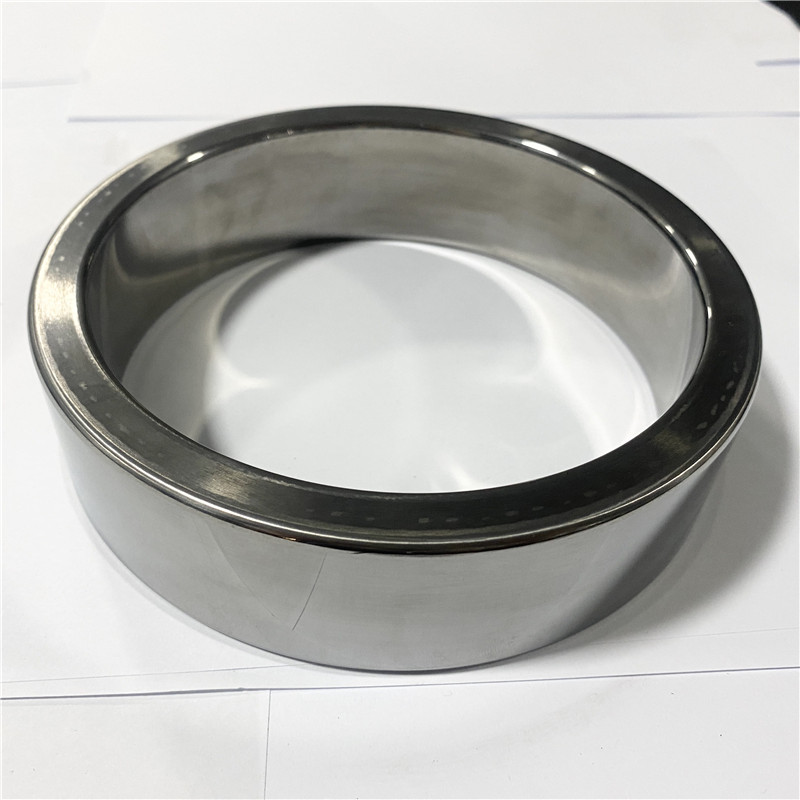

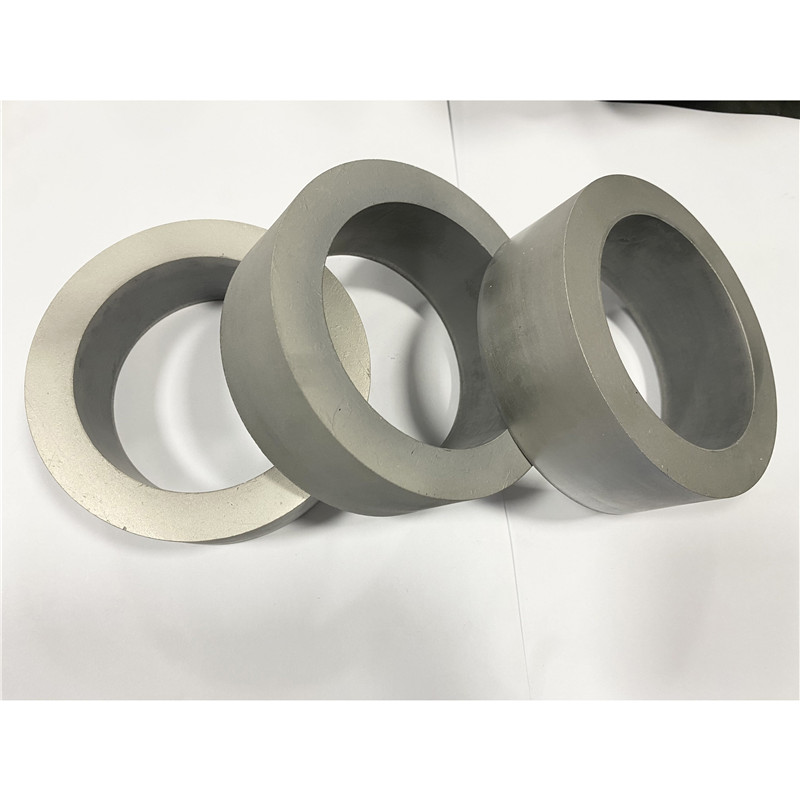

Tungsten carbide roller ring is made by tungsten carbide which could improve the mechanical characteristics of the cold rolled wire. They are used for removing any bends, irregularities, and mills left in the material that is being processed. Also could be used for wire straightening it could ensures that the final wire or rod will be consistent and free off defects.

Tungsten Carbide Roller

100% Virgin Tunsgten Carbide

Grade: K10/K20/K30

Size: Customizable

Standard: GB

Certification: ISO9001

Chemical composition: WC/CO

Property: Resistance to wear/high thermo/high/feed/corrsion

Features

1. Sizes produce according to customer’s size

2. 10 – 20 times life time longer than steel roller ring. Saving maintenance time and cost.

3. High wear resistance.

4. High heat resistance.

5. V – U and custom straightening grooves

RenQiu HengRui Tungsten Carbide can make as per your request, once detailed application and drawing can be provided. High wear resistance and durable performance can be reached with sufficient communication.

Production Process

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Quality Assurance

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC.

Features

Material composition:

1.Physical Properties:

A) Hardness greater than or equal to 92.8 HRA;

B) Density greater than or equal to 14.2 g/cm³;

C) TRS greater than or equal to 4200 N/mm²;

D) Free of ETA phase condition;

E) No contamination by other materials;

F) Porosity = A00 / B00 / C00 ;

G) Uniform and consistent grain size. No grain size can be larger than specified.

H) Chromium carbide grain growth inhibitor only.

2.All the production, coatings are used in Germany, Switzerland, processing equipment;

3.It’s proposed cutting less than 60HRC;

Advantages

1. Good corrosion resistance.

2. High precision.

3. Ra0.2 surface roughness.

4. Made from 100% virgin raw material.

5. Produced go through in-process and final inspection.

6. Stable and continuous production ability.

Our Service

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

Our delivery time

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Our payment term

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Good Wholesale Vendors Tungsten Carbide Brazing Rod - Tungsten Carbide Guide Roller – HengRui , The product will supply to all over the world, such as: Uruguay , Russia , Sydney , Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.