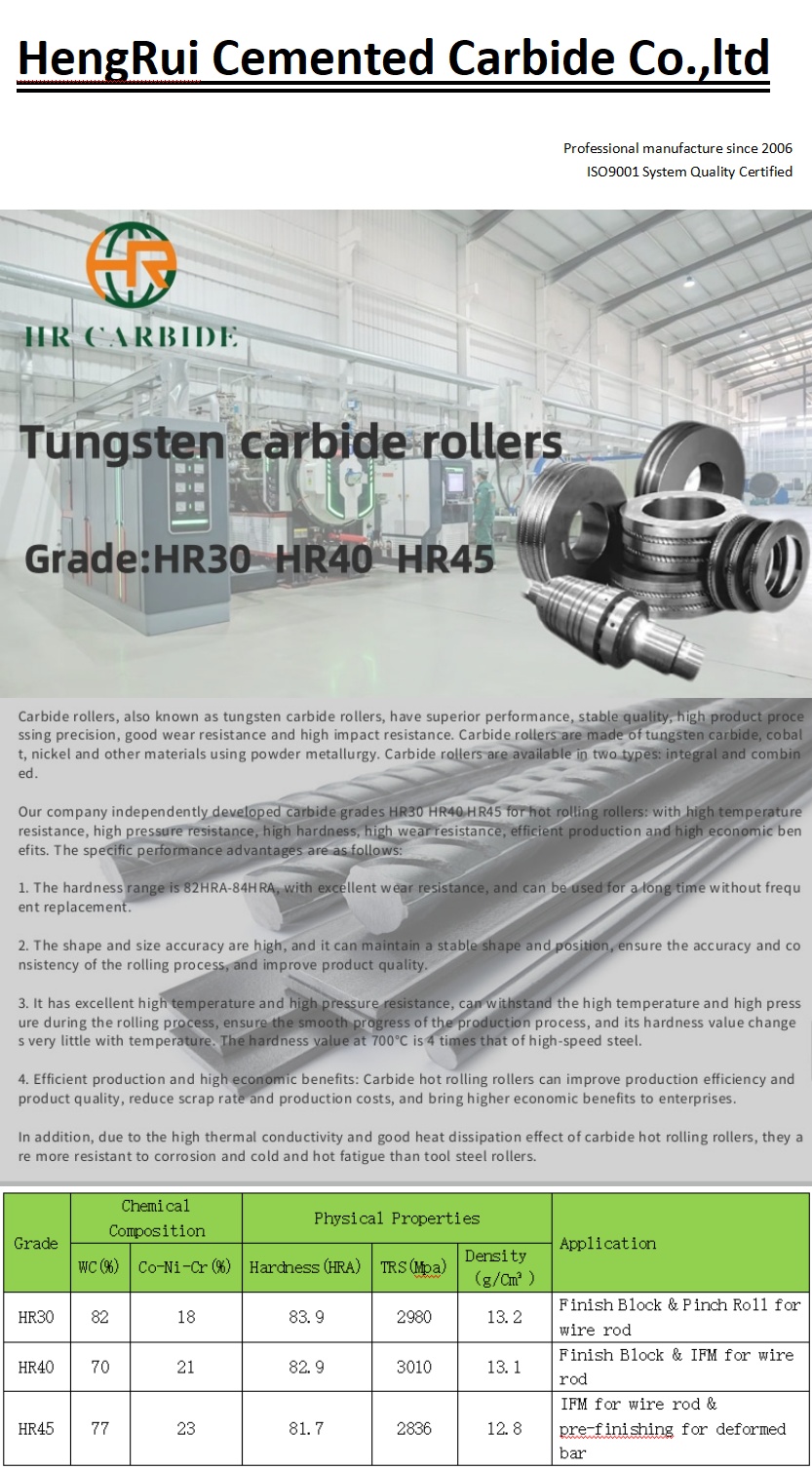

Good wear resistance customized cemented carbide rolls TC rings for wire rod block mills

Wire and rods are hot-rolled between two rolls. Work material deforms and achieves the desired shape and size of the wire or rod. During the process of rolling, these rolls are subjected to severe thermo-mechanical fatigue in addition to wear.

Billets are rolled into wire/rod through multiple pass rolling: Roughing Stand, Intermediate Stand, Block Mill and Finishing Stand.

Our tungsten Carbide rolls for wire rod rolling could provide excellent quality on the rolled material and minimize the downtime.

The type of tungsten carbide rings we could be supplied are Intermediate & Pre-Finishing (Cantilever) Stand Rolls,Composite cemented carbide roll rings,KOCKS tungsten carbide rings.

1. What are the main advantages of choosing your company as a supplier?

We can supply the best quality products, provide one-to-one service, and the lowest price.

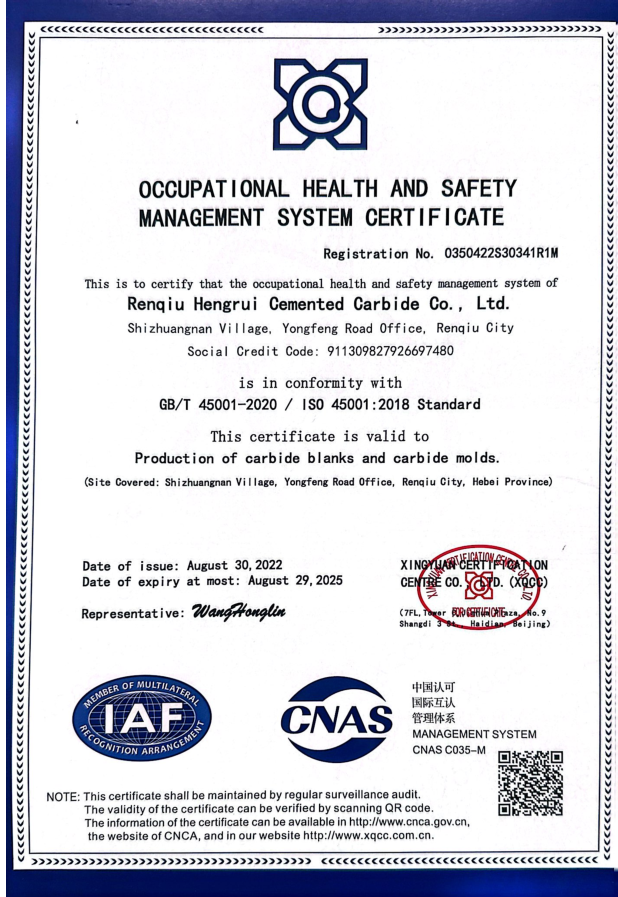

3. How does your company ensure the quality and reliability of its tungsten carbide rollers?

Yes, we have 30+ years of production experience and market experience. Combined with the market, we supply tungsten carbide rollers that best suit market needs.

4. Can you provide examples of successful projects or cooperation with your company?

Yes, our products are sold in Europe, Africa, South America and China.

5. How is your company different from other tungsten carbide roller suppliers in the market?

We provide inspection reports. In addition to strict size inspections, the products will undergo 11 physical tests such as spectral testing, hardness testing, bending strength, etc. before leaving the factory. Only after passing the inspections can they be used.