Good polishing performance Tungsten Carbide Cold Forging Dies Cold Heading mold Yg20c Yg25c

Since its establishment, Renqiu Hengrui Cemented Carbide Co., Ltd. has attached great importance to the talent development strategy. It has a production and R&D team of senior engineers, engineers, and technical backbones, and has established industry-university-research demonstration cooperation with the metal materials disciplines of universities and colleges to be able to Provide comprehensive product design, technical solutions, technical training and technical consultation for all types of users, and assist users in solving various problems encountered during the use of tungsten carbide molds.

Tungsten carbide molds are very wear-resistant and can withstand high pressure and temperature to maintain stable performance. They are well designed to ensure product precision and surface quality. They are suitable for forming a variety of metal materials, including steel, aluminum, copper, etc. Whether it is the manufacture of automotive parts, mechanical parts or electronic products, this mold can play an excellent role. Its excellent performance and durability make it an indispensable tool in the manufacturing industry, which can improve production efficiency and reduce costs.

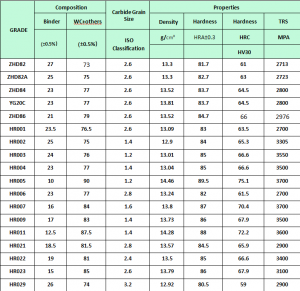

Carbide cold heading dies and cold forging dies are tools specifically used for cold heading and cold forging of metals. They are made of high-precision machining and the highest quality tungsten steel grades to ensure long service life and excellent performance. These dies have extremely high wear and corrosion resistance and can maintain stable working conditions under high pressure and high temperature environments. They are well designed to ensure the production of high-quality products and can meet the processing needs of various complex shapes and sizes. Whether it is used for the production of automotive parts, building hardware or other mechanical parts, cement carbide cold heading dies and cold forging dies can provide reliable processing solutions. Whether you are looking to increase production efficiency, reduce production costs, or improve product quality, these dies can meet your needs.

We can send international express such as DHL, FedEx, UPS, SF Express, etc. We can also choose lower-cost shipping methods such as sea transportation and air transportation.

1. What are the advantages of choosing tungsten carbide molds?

The wear resistance, bending strength and durability of tungsten carbide molds are unmatched by ordinary mold steel. High-quality tungsten carbide molds can extend the service life of the mold by 3-10 times, so choosing tungsten carbide molds is the best choice.

2. What are the requirements for tungsten carbide for cold heading dies and cold forging dies?

Cold heading dies and cold forging dies have strong impact resistance and require a high proportion of cobalt content to ensure good impact resistance, usually requiring more than 20% cobalt content.

3. What is the biggest advantage of choosing your products?

We have decades of experience in cemented carbide production. From raw materials and processing, we have better price advantages and technical experience support, and can provide complete after-sales