Factory Outlets For Tungsten Carbide Molding Dies - Tungsten Carbide Cold Heading Dies High Wear-Resistance – HengRui

Factory Outlets For Tungsten Carbide Molding Dies - Tungsten Carbide Cold Heading Dies High Wear-Resistance – HengRui Detail:

Why Choose Us

1. Chinese factory specialized in processing and production, ISO certification.

2. Multiple sizes and types available for OEM.

3. Made of 100% original high-quality materials

4. Professional production team, fast delivery

5. Free professional after-sales service and technical support

Production description

Tungsten carbide cold heading dies for fasteners,high impact resistance,toughness ,wear resistance,and quality consistency.You are encouraged to use our professional carbide grades for cold heading &punching die nibs. Power metallurgical Compacting dies and other industries.For stable performance and high-cost-effectiveness.They have been proved to be ideal in making non-ferrous metal, ferrous metal and their carbides.

detail

Some of the wear products that we manufacture from tungsten carbide are:

1. Crusher tips and jaws

2. Conveyor scraper blade tips

3. Shot blast nozzles,lance tips,wheel blades

4. Tipped static and rotary recycling shredding blades

5. Impact and wear plates

6. Faced bar hammers

RenQiu HengRui Tungsten Carbide can make as per your request, once detailed application and drawing can be provided. High wear resistance and durable performance can be reached with sufficient communication.

Production Process

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Quality Assurance

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC.

Features

The tungsten carbide heading die are used for cold punching and heading of srew and nuts, it is wear resistance and high toughness.Also, it is the ideal in making non-ferrous metal, ferrous metal and other carbide.

Main grade: YC15,YC20,YT15, we can also change according to the customers request.

Advantages

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer’s application.

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

Our Service

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

Our delivery time

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Our payment term

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match ourcustomers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.

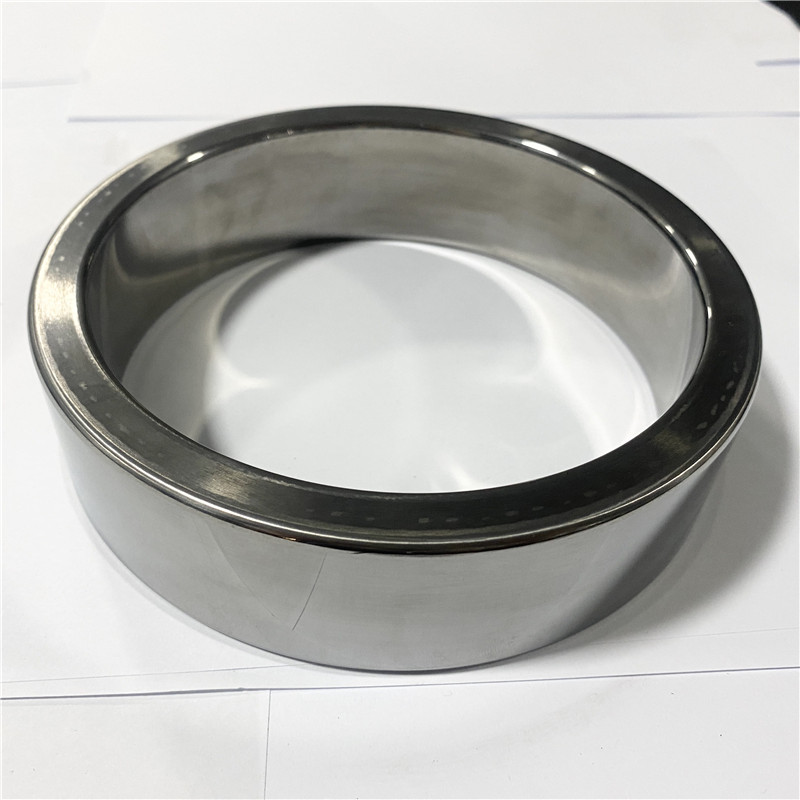

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers, hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Factory Outlets For Tungsten Carbide Molding Dies - Tungsten Carbide Cold Heading Dies High Wear-Resistance – HengRui , The product will supply to all over the world, such as: Birmingham , Estonia , Guyana , All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.