8 Year Exporter Tungsten Heavy Metal - Tungsten Carbide Wire Drawing Dies – HengRui

8 Year Exporter Tungsten Heavy Metal - Tungsten Carbide Wire Drawing Dies – HengRui Detail:

Video

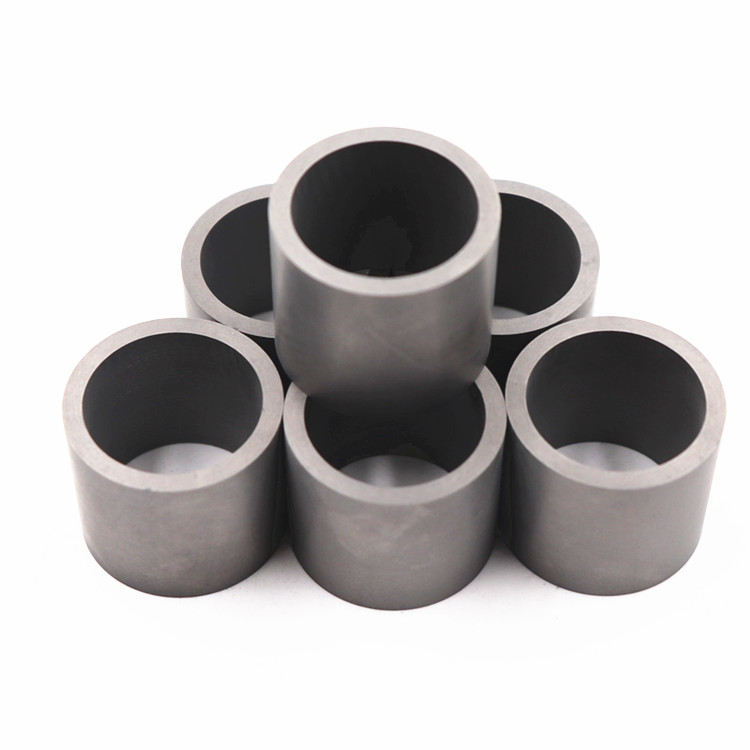

Product Description

YG6X: Suitable for the production of carbide dies with drawing inner holes which are smaller xn--than6-1de.00mm.

YG6: Used for the non-ferrous metal round bar, which has drawing inner holes smaller than Φ20mm, and the drawing dies, which has inner holes smaller than Φ 10mm.

YG8, YG10: Applied for drawing steel and the production of non-ferrous metal round bars & pipes.

YG15: Used for steel rods and pipes which have a high shrinkage.

Tungsten carbide wire drawing dies have the following features which ensure the high durability:

1. Strong power resistance

2. Excellent wear resistance

3. Sufficient thermal stability

4. Excellent process ability

Matters needing attention and maintenance of carbide wire drawing dies

1. Ensure the stability of the drawing machine

For each drawing drum, the over-line guides should be smooth, flexible, and strictly controlled for beating tolerance. If the drum is found, the guide wheel has a worn trench, and the drawing dies should be repaired in time.

2. Good lubrication

Good lubrication is important to ensure the surface quality of the wire and extend the service life of the mold. The lubrication index should be checked frequently, removing the copper powder, and impurities in the lubricant, so that the equipment hole can not be polluted. If the lubrication doesn’t work, it must be replaced in time and cleaned.

3. Reasonable allotype

A reasonable allotype is to ensure the surface quality of the wire and control size accuracy, reducing the wear of wire drawing drum and equipment operating load. For sliding wire drawing machines, it is necessary to familiarize yourself with the mechanical elongation of the equipment. The sliding coefficient is reasonably selected, which is the primary step of fitting the mold.

4. Appropriate adjustment of the size for the compression angle

The surface reduction rate of each drawing and the material of the drawn wire are also closely correlated with the compression angle of the respective mold. The size of the compression angle is appropriately adjusted according to the size of the surface reduction rate.

5. The timely replacement of the aging drawing dies

When the drawing die reaches the service life, please replace it in time for repairing treatment to avoid excessive causing scrap the wire.

Summary

The tungsten carbide wire drawing dies are widely used for drawing in various industries. It has high hardness, excellent thermal stability, high durability, and long service life and is one of the best mold materials.

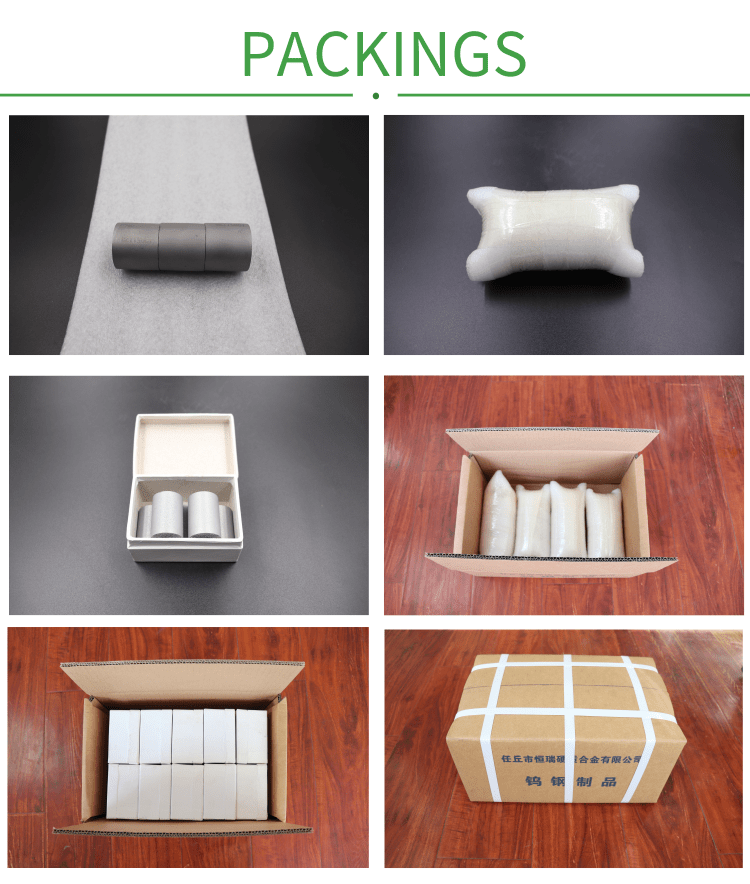

Package

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers, hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for 8 Year Exporter Tungsten Heavy Metal - Tungsten Carbide Wire Drawing Dies – HengRui , The product will supply to all over the world, such as: Iraq , Nairobi , Argentina , Our expert engineering team will generally be prepared to serve you for consultation and feedback. We are able to also offer you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and products, please speak to us by sending us emails or call us quickly. In an effort to know our products and company extra, you may come to our factory to view it. We will generally welcome guests from all over the world to our business to create business relations with us. Please feel cost-free to speak to us for small business and we believe we'll share the best trading experience with all our merchants.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.