3D TC Roller Ring HengRui tungsten carbide rolls for reinforcing steel wire

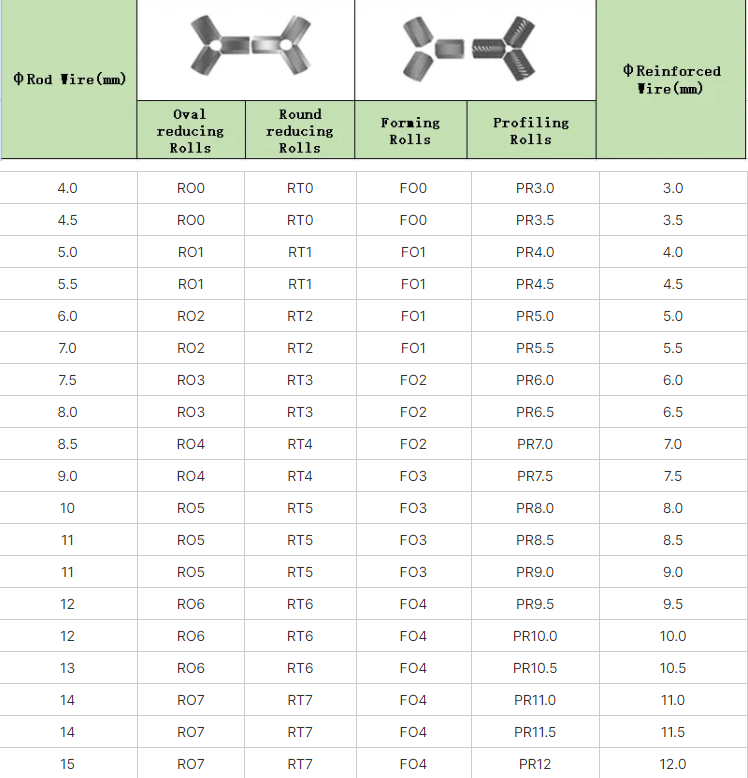

Service is to be available for the design, groove machining and rid machining of composite cemented carbide roll. Various matching tools can be provided for machining composite e cemented carbide roll.

Bonding-type and thermal interference-type composite rolls can be provided according to customers’requests. Special cemented carbide grades for rolling ribbed steel bars and rods can be developed according to customers' requests.

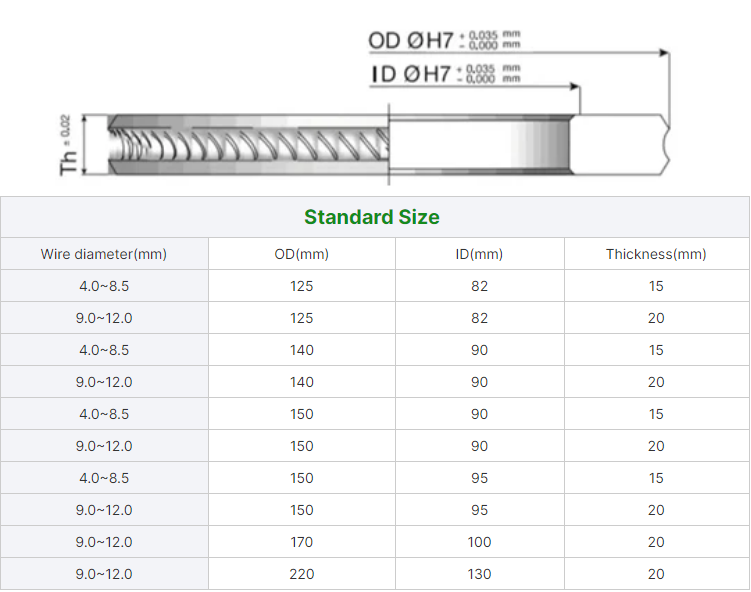

Various cemented carbide roll rings are available with diamete er of 300~400mm and thickness of 30~150mm for rod reducing and sizing machines.

Our service commitment: Each of our professional products is equipped with a professional sales engineer to provide technical consultation and door-to-door service to relieve your worries. If you have any requirements, we promise to arrive at the site within 24 hours in the province and 72 hours outside the province. We will visit regularly and listen to your requirements. Let you enjoy the "Diamond" brand and buy with confidence. We firmly believe that it is the customers who have made our "Diamond" brand. Considering the customers is considering ourselves. The opinions and suggestions of customers are our driving force for progress, and satisfying customers is our eternal pursuit.

1. What are the main advantages of choosing your company as a supplier?

We can supply the best quality products, provide one-to-one service, and the lowest price.

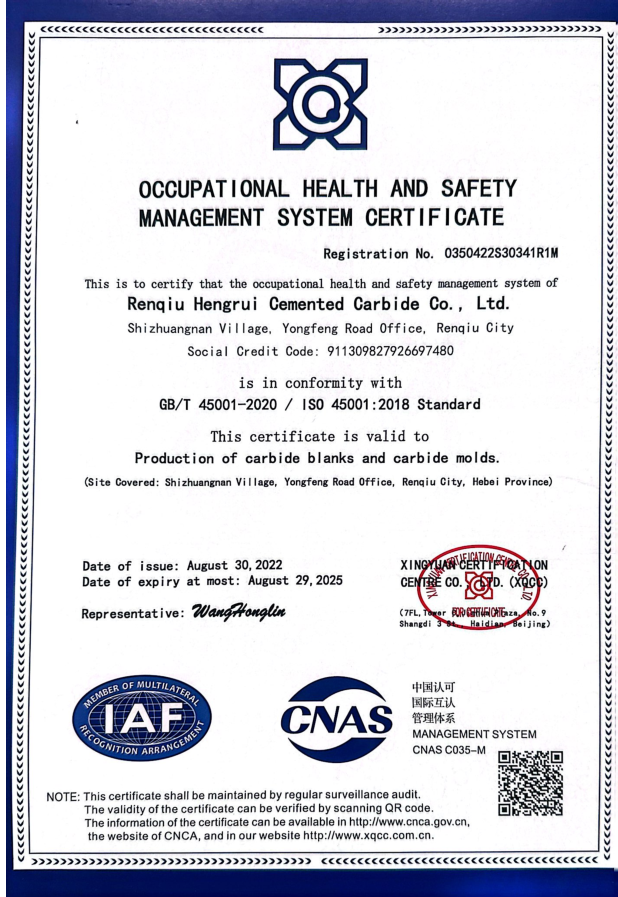

3. How does your company ensure the quality and reliability of its tungsten carbide rollers?

Yes, we have 30+ years of production experience and market experience. Combined with the market, we supply tungsten carbide rollers that best suit market needs.

4. Can you provide examples of successful projects or cooperation with your company?

Yes, our products are sold in Europe, Africa, South America and China.

5. How is your company different from other tungsten carbide roller suppliers in the market?

We provide inspection reports. In addition to strict size inspections, the products will undergo 11 physical tests such as spectral testing, hardness testing, bending strength, etc. before leaving the factory. Only after passing the inspections can they be used.