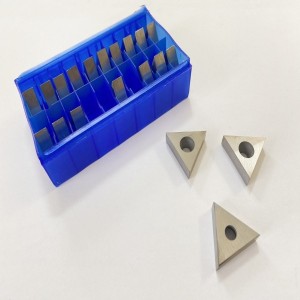

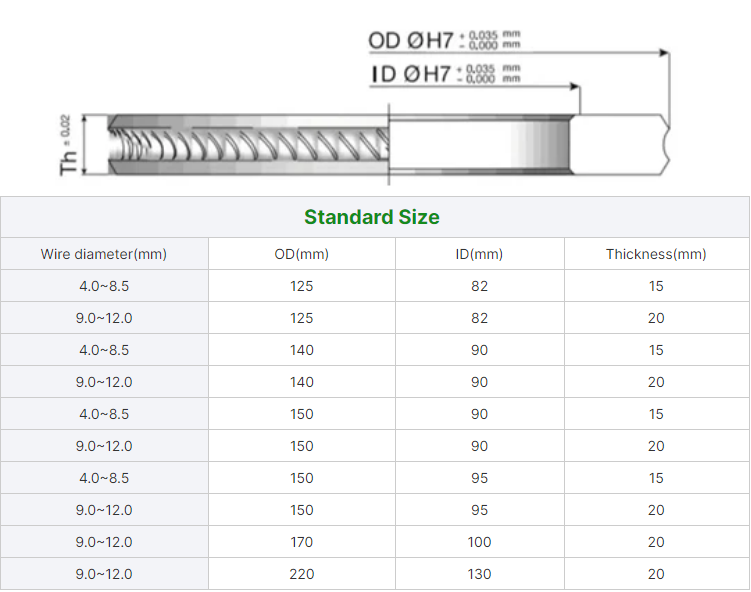

100% virgin material 150*15*95 YG15 tungsten carbide roller for rebar

The rolling force, rolling torque, and thermal conductivity properties of different stands are different, so different stands should use different brands of carbide rolls. In the design process of cemented carbide roll materials, it is necessary to ensure a reasonable match between the strength, hardness and impact toughness of the rolls. A database of thermophysical parameters of different alloy grades should be established, and computers should be used to optimize roll material design.

During the rolling process, the wear of cemented carbide rolls is not only affected by external conditions such as temperature, rolling pressure and thermal shock load, but also by internal factors such as the existence between the hard phase WC and the bonding phase Co/Co-Ni-Cr. It is affected by quite complex physical and chemical reactions. This makes the wear situation more complicated. Therefore, it is necessary to strengthen the research on the mechanism in this aspect.

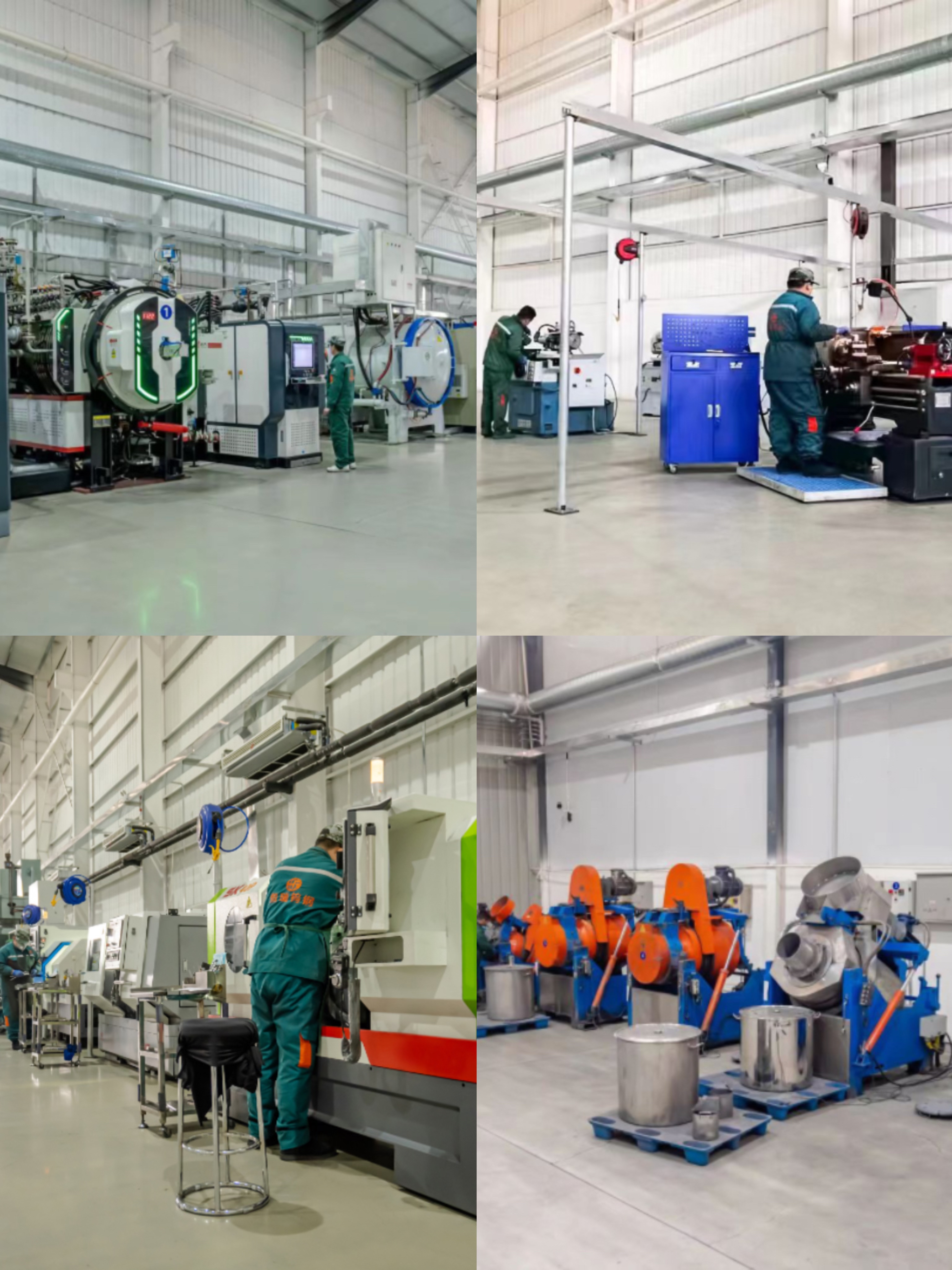

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Our first lot of products from the sintering furnace is carbide heading blank dies in 2006

We have independently developed 48 grades and will be more in the future.

We have replaced our equipments twice during 5 years to ensure the quality and improve the efficiency thus decrease the price to be more competitive

our value faith is solve the problem of customer

Delivery within 48 hours

We have engineers with 30 years of experience and can customize materials upon request.

1. We ensure that our service process can solve all your problems.

2. Professional, dedicated and attentive, we are always consistent.

3. Pursue excellence in technology and wholeheartedness in service.

4. To maintain a high sense of responsibility and full enthusiasm for work, we should serve customers with all our heart and soul.

For orders less than 100kg, we will ship the goods 3 ~7 days after receiving payment. For orders greater than 100kg, we will ship the goods within 10 ~ 15 days.

Production is after 50% advance payment, and the balance is paid before shipment.

We only accept 100% advance payment for trial orders before production.